Company Information

Ask for more detail from the seller

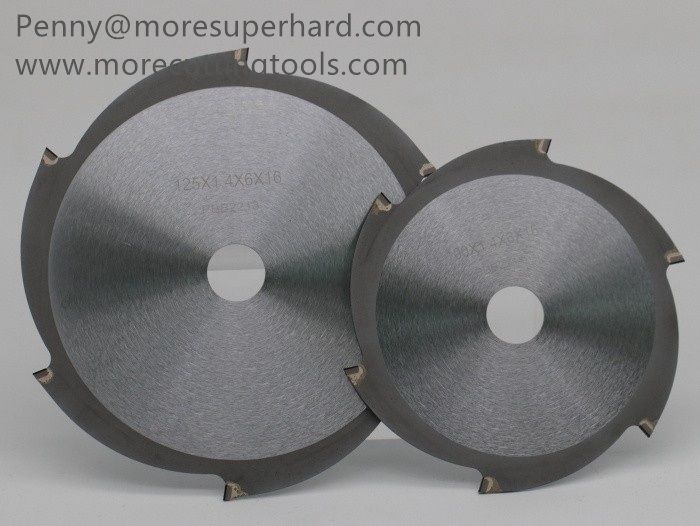

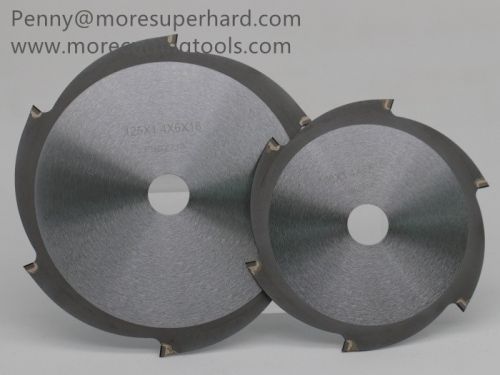

Contact SupplierPCD saw blade is used for cutting and grooving non-metallic materials, nonferrous materials, the particleboard woodworking industry, and the Ultra-precision processing industry.

Application: cutting particleboard, electronic circ.

Specification

PCD Cutting BladesWhat are PCD saw blades?

PCD Blades are blades for circular saws but compared to a standard circular saw blade where the teeth are tungsten carbide tipped, PCD blades have teeth made of Polycrystalline Diamond.

What is a polycrystalline diamond?

Diamond is the hardest material in nature and is the most resistant to abrasion.

Polycrystalline Diamond (PCD) is an artificial diamond produced in a laboratory through a sintering process. It is an extremely resilient material where diamond crystals are bonded to a base material of tungsten carbide.

During the sintering process, the spaces between the PCD grains are filled with a cobalt alloy and the single diamond grains bond to each other.

This results in a material that matches no other in terms of toughness, durability and resistance, making polycrystalline diamond an excellent cutting material and perfect for use in cutting tools especially where the material is particularly abrasive. It also contributes to the diamond tool having a longer cutting lifetime.

Diamond-tipped saw blades are an excellent choice when cutting larger volumes of homogenous material.

In particular, a polycrystalline diamond tipped (PCD) blade will excel in applications such as cutting melamine and HPL coated panel products, solid surface materials such as Corian, cement fiber board panels, and fiberglass, among others, which are all very hard on conventional carbide-cutting tools.

The PCD saw blade is used for cutting and grooving non-metallic materials, nonferrous materials, the particleboard woodworking industry, and the ultra-precision processing industry.

A diamond blade can be re-sharpened, and the number of times it can be sharpened depends, among other factors, on the height of the diamond tip the blade is manufactured with.

-Typically, our diamond blades have a 6.5mm tip height which can yield up to 12 sharpenings.

-A more economical blade (lower initial cost) is available with a 5mm tip height which will yield about 6 sharpenings.

-With normal wear, about 0.5mm of the PCD is removed with every sharpening.

-Diamond blades can returned to our facility when dull, They require highly specialized machinery to service.

penny AT moresuperhard

15938109295