Company Information

Ask for more detail from the seller

Contact SupplierProcessing Part: Aluminum alloy wheel hubs for car, Aluminum Alloy Outer Circle, Head Face

Processing Way: Turning, Semi-Fishing, Fishing

Characters: PCD Turing Tools Have Long Service Life, High Efficiency And Work Pieces Have Higher Brightness, Etc.

During the wheel hub machining process, uses the PCD wheel hub tool for repairing and refurbishing the aluminum alloy wheel hub rim.

Specification

Application of PCD wheel hub turning tools:

The PCD wheel hub tools are used for turning and finishing aluminum alloy wheel hub rims for cars.

Advantages of PCD tools for wheel hub cutting:

▶ The tool bits of the PCD wheel hub turning tools use PCD & PCBN blanks by E6. The cutter arbor uses high-quality tungsten carbide and tool steel

▶ Advanced Welding Technology To Ensure PCD turning tools No Turning, No Welding Off, No Carbonization, Long Life

▶ Welded Integral Hub Tools with Good Tool Rigidity, Good Shock Resistance, Stable Performance, And Large Feed

▶ It Is An Aluminum Car Wheel, Motorcycle Aluminum Wheel Hub, Electric Vehicle Aluminum Wheel Hub The Most Commonly Used Diamond Blade For Fine Turning.

PCD wheel hub turning tools Classification:

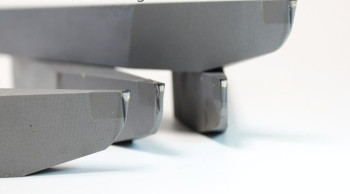

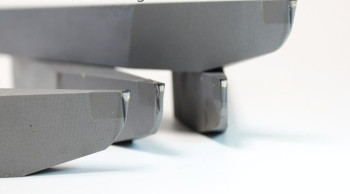

1. Welded Integral Hub Tools. (Can Be Designed To Meet Specific Customer Requirements.)

The PCD blade and the tool holder are welded together, which has good thermal conductivity, stability and impact resistance. The size can be customized according to customer needs, which saves the debugging time for the matching of the blade base and the tool holder. In turn, the rapid response of the processing site is achieved. Mainly used for rough machining of wheel hubs.

Common Specifications Include 25*25 And 20*20 Two Kinds Of Body Specifications, Divided Into Forehand And Backhand.

▷The Dimensions Of The Cutter Head R Are Generally R4, R3, R2.5, And R2.

▷The Protruding Part Of The Welding Head Of The Blade Body Is Welded With a Hard Alloy To Reinforce The Strength.

▷The Extension Length Is Determined By The Processing Of The Hub Size And The Depth Of The Rim.

Advantages: Good Tool Rigidity, High Welding Strength, Good Shock Resistance, Stable Performance, And Large Feed.

Disadvantages: Inconvenience Of Tool Change, High Production Cost, Inconvenience Of Mailing, High Postage, And Inconvenience Of Warehouse Management.

2. Replaceable Mechanical Clamping Type.(Clip Type)

V type clip

It is suitable for roughing, semi-finishing and finishing of wheel hubs, especially the surface finishing of wheel hubs after painting. It has the characteristics of extremely high life, durable high brightness and dimensional consistency. It can better meet the processing requirements of the current wheel industry users' automated production lines.

R type clip

The mainstream tools used in wheel hub processing have high rigidity, stability and impact resistance, and meet the requirements of customers for heavy cutting and interrupted cutting. Different chipbreaker geometries can also be designed according to customer needs.

Advantages: Convenient Tool Change, Easy Manufacture, Low Manufacturing Cost, Convenient Mailing, And Easy Mass Production.

Disadvantages: Tool Rigidity Is Slightly Weaker And Not Suitable For Large Feed Processing.

3. Homemade Mechanical Clamping

Hub Blade, Belonging To The International Standard Size Blade, Using a Standard Carbide Substrate, High-Quality PCD Cutter Head. The Blade Has Wide Applicability, Excellent Quality, And Can Be Designed And Processed According To The Needs Of Customers.