Company Information

Ask for more detail from the seller

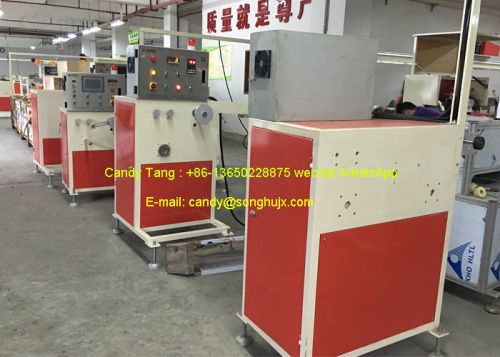

Contact SupplierPe hot water pipe making machine 20-32 mm

description:

1 pe plastic pipe production line consists of electrical control system, extruder, and die head;

calibrating and cooling system, haul-off, winder

2. According to different raw material and product specifications, screws with different ratios of length

diameter and compression, barrels of different structures and proper driving devices are adopted so

as to make plastic products with high quality.

3. Our plastic extrusion lines based on plastic extruders:single screw extruder,conical twin screw

extruder and parallel twin screw extruder.

4 . Adopting frequency conversion governor,hear surface gear box which feature stable running, strong

bearing and long life. According to customers’ requirements, computer control or conventional control is

optional.

5. Pe plastic pipe extruding machine adopts high efficiency single screw extruder, equipped with the

siemens plc controlling system. It can ensure the whole line automatic controlling of high capacity, stable

extruding with the suitable changing of different units could realize the production job of pe pipe

applications:

1. Mainly used for hot water transport. Used in house, under floor, for keep house warm

competitive advantage:

1.the unit main electric appliance part both uses the imported product and the movement stably reliable.

The unit all control pressed key uses the integration design,the operation simple and quickly.

2. Stable running, low noise,strong bearing and long life use

3. High out put,high effciency and easy to operate

4. Double station winder