Company Information

Ask for more detail from the seller

Contact SupplierDetails

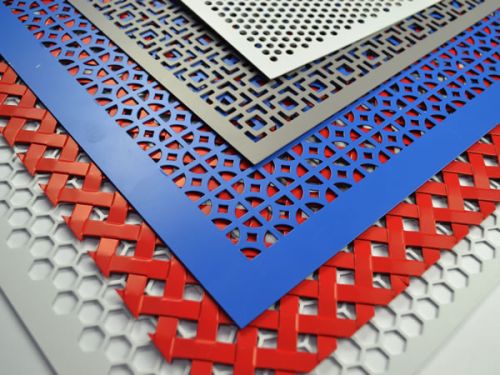

1. Name: Perforated metal mesh is used on different materials marked with holes of different shapes to suit different needs.

2. Material: galvanized plates, cold plates, stainless steel plates, low carton steel PVC plates aluminum plates,aluminum magnesium alloy plates,etc.

3. Hope shape:log holes,round holes,triangle holes,lightly pull scale hope,other pull wire netting etc.

4. Using: on the filtration of auto gas engine,the classification and filtration of mine,medicine,cereals and grains,indoor sound insulation,ventilation of grain depot,etc.

5. Specification:

Thickness of roll plate: 0.2mm-1mm

Length of plate: 20m

Opening: 1.5mm-10mm

Thickness of plate: 0.2mm-20mm;width*length�1.5m*5m

Opening: 0.5mm-200mm

6. Punching way

1) continuous punching in the same direction: the use of partially overlapping rectangular metal mesh mold processing methods, can be processed long hole, trimming and the like.

2) continuous molding: molding is larger than the perforated metal mesh size of the mold forming methods, such as large-sized shutters, roll bars, rolling stairs and other processing methods.

3) nibble: Use small round mold with a small step away from the arc-shaped continuous punching processing methods.

4) continuous punching multi-directional: the use of small metal mesh macroporous mold processing methods.

5) a single molding: mold shape by forming a shallow drawing processing methods.

6) single-shot: a single complete punching, including linear distribution, circular distribution, circular distribution, punching holes in the grid.

7) forming the array: processing workpieces of the same or different in the way more than a large board.