Company Information

Ask for more detail from the seller

Contact SupplierSensors

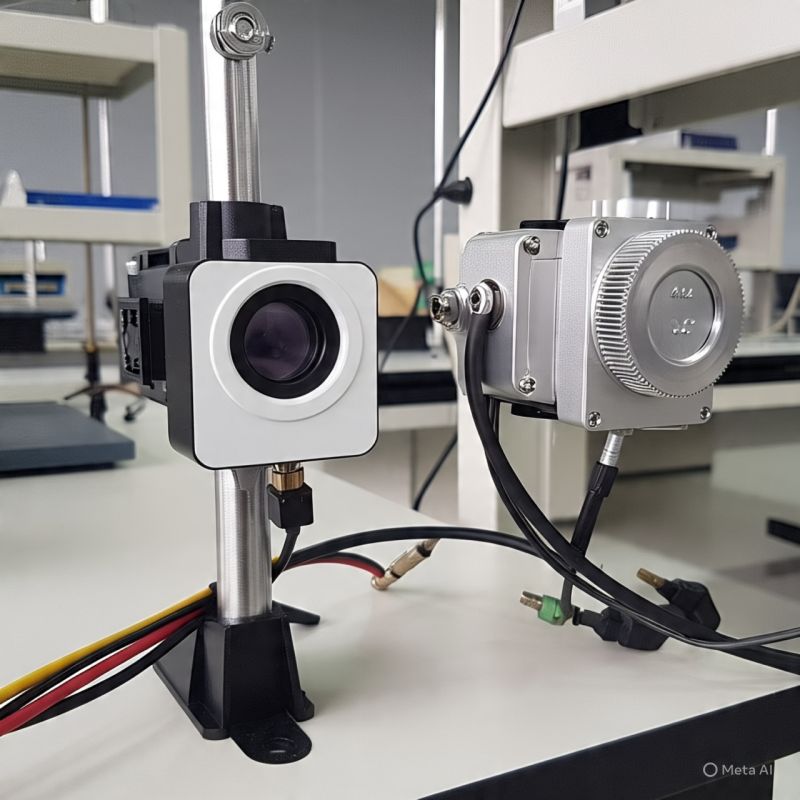

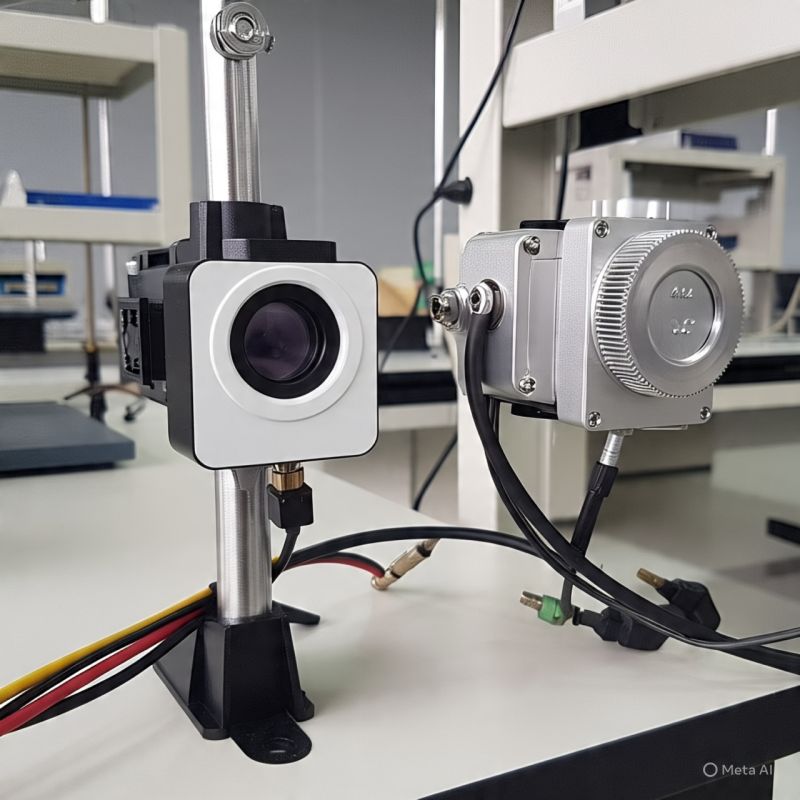

Photoelectric and inductive sensors are critical components in industrial automation systems. Designed for non-contact object detection, they ensure reliability, speed, and safety across conveyor systems, packaging lines, CNC machines, robotics, elevators, and production processes. These sensors enable real-time feedback for controlling position, presence, metal detection, and material movement.

🔍 1. Photoelectric Sensors

✅ Working Principle:

Photoelectric sensors work by emitting a light beam (LED, infrared, or laser). Detection occurs when this beam is interrupted or reflected back by an object.

🔄 Types:

Through-Beam:

Uses separate transmitter and receiver

Long sensing distance (up to 10 meters or more)

High precision

Retro-Reflective:

Uses a reflector; detects interruption in the return beam

Easy alignment; range up to 4–6 meters

Diffuse Reflective:

Senses light reflected directly from the object

Sensing range: 10 cm to 1.5 m

Laser-Based:

leelavati automation

Sharp, narrow beam for accurate, small-part detection

Used in fine assembly and positioning tasks

⚙️ 2. Inductive Proximity Sensors

✅ Working Principle:

Inductive sensors detect metallic objects by generating an electromagnetic field. When metal enters the field, it changes the inductance, triggering a signal.

🔄 Types:

Flush (Embeddable):

Mounts level with surfaces

Offers short sensing distances

Non-Flush (Protruding):

Extends from mounting surface

Provides longer sensing distances

Analog Output Inductive:

Offers continuous distance feedback (not just ON/OFF)

📐 Specifications & Units

ParameterPhotoelectric SensorsInductive Sensors

Sensing Distance10 mm – 10 m+1 mm – 40 mm

Target DetectionAny object (opaque/reflective)Only metallic objects

Output TypesPNP/NPN, Relay, Analog, IO-LinkPNP/NPN, Analog, IO-Link

Voltage Range10–30V DC or 24V AC10–30V DC

Operating Temperature–25°C to +70°C–25°C to +80°C

Protection RatingIP65 / IP67 / IP69KIP65 / IP67 / IP68

🏭 Applications

Photoelectric SensorsInductive Sensors

Detect objects on conveyorsDetect metal parts in automated assemblies

Label and package detectionPosition sensing in metal machinery

Transparent object sensing (e.g., bottles)End-stop detection in actuators

Print mark and barcode sensingShaft position monitoring

Color or edge detection in printing/textilesProximity sensing in welding, cutting, robots

leelavati automation

🧱 Construction & Materials

Housing: Stainless steel, nickel-plated brass, ABS, or polymer blends

Lens/Window: Acrylic or tempered glass

Connectors: M8/M12, cable tail, or terminal block

Protection: IP65–IP69K for dust, water, and chemical resistance

Sensors can be designed for:

Harsh outdoor conditions

High-pressure washdowns

Hazardous/explosive environments

📤 Signal Outputs

Output TypeFunction

PNP/NPNDigital switching output for logic control

Analog (0–10V / 4–20 mA)Variable signal based on distance

RelayMechanical switch, slower but rugged

IO-LinkDigital communication for smart diagnostics

leelavati automation

💰 Price Range (Indicative)

Sensor Type

Basic Inductive Sensor

Analog Inductive Sensor

Basic Photoelectric Sensor

Laser Photoelectric Sensor

IO-Link Enabled Smart Sensor

based on sensing range, output type, housing material, and certifications.

📄 Warranty & Reliability

Typical warranty: 12 to 24 months

Lifecycle: Up to 100 million switching operations

Features:

Built-in LED indicators

Overload and reverse polarity protection

Self-teach or auto-tune options

leelavati automation

Sensor health diagnostics in smart models

🧠 Smart Factory Integration

Advanced sensors support:

Predictive maintenance

Remote diagnostics

Edge computing

IoT dashboards

Energy-efficient operation

They integrate seamlessly into modern PLC, SCADA, and BMS systems via IO-Link, Modbus, or analog inputs, supporting Industry 4.0 applications.