Company Information

Ask for more detail from the seller

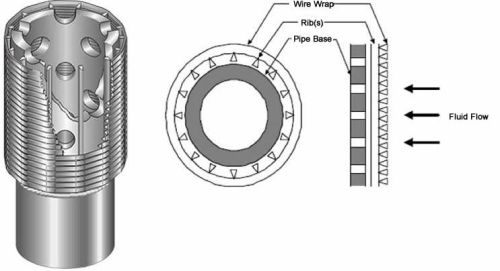

Contact Supplierwe are offering pipe based wire wrapped screen. wire wrapped screen consists of a wire-wrapped jacket and a perforated pipe. keystone shaped wire are helically wrapped around the vertical ribs and each point of contact is welded. this special shaped wire is designed for decreasing the chances of sand plugging the screen, self-cleaning action and reducing flow friction. the diameter and number of ribs depends on the strength and size the screen. the more the number is, the stronger the screen is. wrapping should be accurately controlled to form uniform & precise gauge for reliability.

pipe based sand screen is used in stand-alone completions with well sorted formulations or in combination with gravel packed completions. it provides superior strength & accurate slot openings. compared with slotted liner, its larger inflow area maximizes the production.

wire wrapped screen is wedge wire around perforated pipe

v wire wrapped sand screen

product description:

material for wire: stainless steel 316l or nickel alloy 825;

material for base pipe: upon request;

wire width: 0.090 in. (2.286mm);

slot depth: 0.100 in. (2.54mm);

slot opening: from 50 micron up to 2000 micron.

applications:

cased- and open hole environments.

suitable for gravel-pack and standalone operations.

sand free production in vertical or horizontal wells.

features & benefits:

very accurate slot opening;

rotating ability during installation;

high strength and superior corrosion resistance;

keystone shaped wire provides maximum erosion resistance & strength;

higher number of round ribs gives ultra-high strength and tolerance for the service life;

larger inflow area than slotted liner for maximum production;

all api and ansi pipe sizes are available;

customized end fittings and thread connections.

wire wrapped sand control screen construction

wire wrapped screen structure