Preferred Buyer From :

All over the world

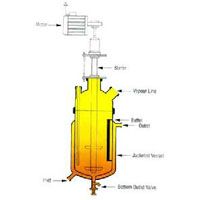

Volume: 100litres to 10000 litres working volume pilot scale and plant scale reactors tailor made to customers requirement

Pressure Range: up to 100 bar

Temperature Range: up to 300°C

Material:....

View More Details