Company Information

Ask for more detail from the seller

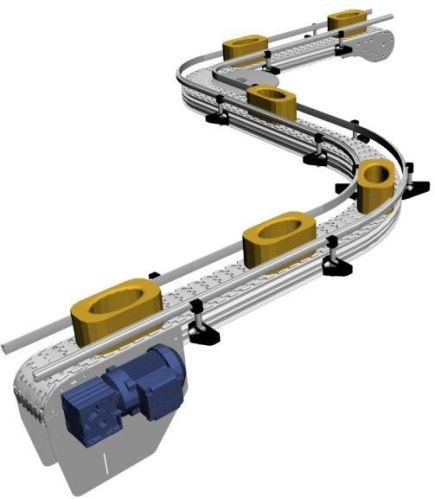

Contact SupplierDrive Units & Idler Ends

There are various types of drive units that are available to move the conveyor chain as

mentioned below:

-End Drive Units pull the chain from one end of the conveyor. The chain returns on the

bottom of the conveyor beam, passing through an idler end at the other end.

-Intermediate Drive Units are located at an intermediate point of the conveyor,

having an idler end at both ends of the conveyor.

-Catenary Drive Units are used in applications where chain running on the bottom

track is either not desired or not possible. e.g.: closed loop conveyor.

-Combined Drive Units are those that have a drive unit and an idler end together in

one unit. This is used in areas where transfer from drive unit of one conveyor to

another of the same size is required. The transfer area is provided with either steel

plate, gravity transfer rollers or powered transfer rollers depending on product type

and length.

Bends

To achieve a change of direction, both horizontal and vertical bends can be used to

accomplish it. The several types are as follows:

1)Horizontal Wheel Bend

-The bend force is taken by a free wheel and lowest friction is obtained by using a horizontal wheel bend. Moreover, the smallest turning radius for the chain is achieved using wheel bend. Select wheel bend whenever possible.

2)Horizontal Plain Bend

-For larger radius, horizontal plain bend is used as analternative.

3)Vertical Bend

-To achieve a change of direction in the vertical way, vertical bends are used.

Guides

Guides are provided along the conveyor in order to hold the products in position while in motion.The guide rails keep the products from falling off from both sides of the conveyor, whereas theguide rail brackets hold these guide rails in position.

Support

The various components for conveyor support are as follows:

1)Support Feet

-Stainless steel support feet or foot caps.

2) Support Beams

-aluminium extruded profile in 40x40mm and 80x80mm

3)Beam Support Brackets

-to connect conveyor beam to support beam.