Company Information

Ask for more detail from the seller

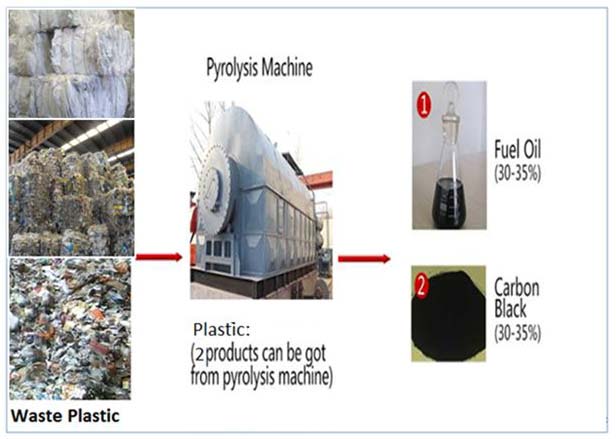

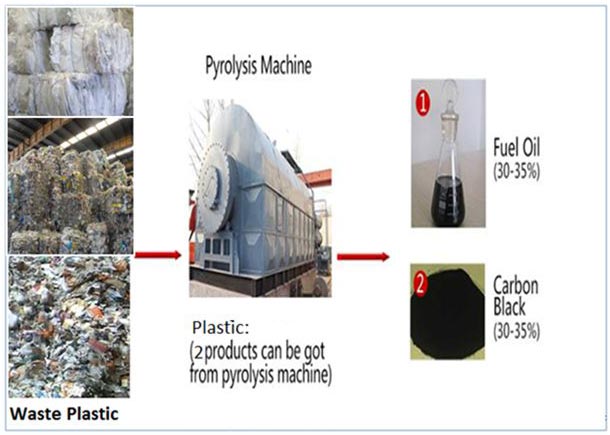

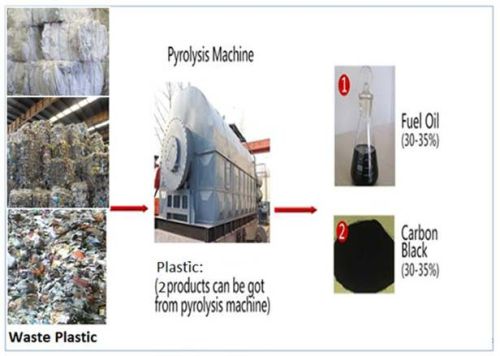

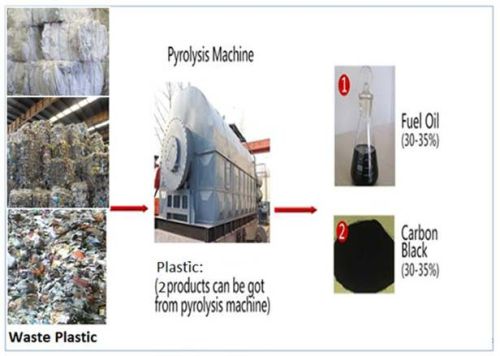

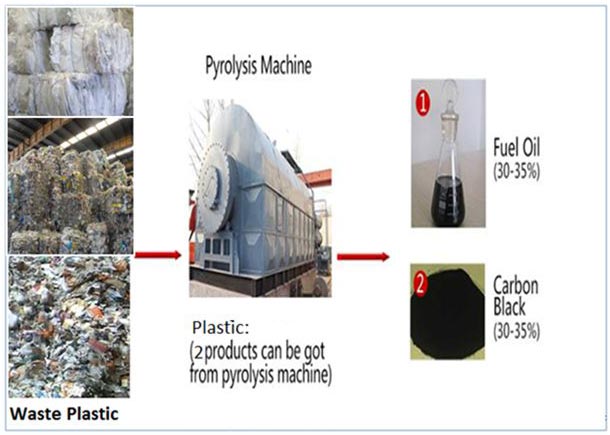

Contact SupplierWe manufacture, export and supply highly efficient Plastic Recycling Plant that makes use of the pyrolysis process for the recycling of the waste products. Pyrolysis is the decomposition of organic compounds under oxygen free (anaerobic) atmosphere that produces gas, oil, carbon black. Efficient industrial pyrolysis is a process to treat the rubber and industrial plastic wastage. The raw materials used in our Plastic Recycling Plant are paper mill waste, cement bag, cap of pet bottle and road waste soft plastic. As a result of pyrolysis of waste plastic, we got furnace oil (30-35%), carbon black (35% to 40%) and gas (20% - 25%).

Features of the plant :

Project Planning & Implementation (For the 10 ton/day capacity) :

Other Arrangements to be made by Client : Storage tank of oil (Available locally), Civil Work, Local Worker & labour, Hydro crane, Plumber, Electrician, Gus cutter, Welder.

Terms & Condition :

Estimated Operational Cost and Return on Investment for Waste Plastic :

The analysis is based on the conjecture of 10 tons/day capacity unit operating for 300 days a year;

Raw material waste Plastic (waste plastic paper mill waste, polythene, carry bags, road waste plastic, cement bags, PP Plastics): 6 tons per day*300 days = 1800 ton/ year.

Total output :

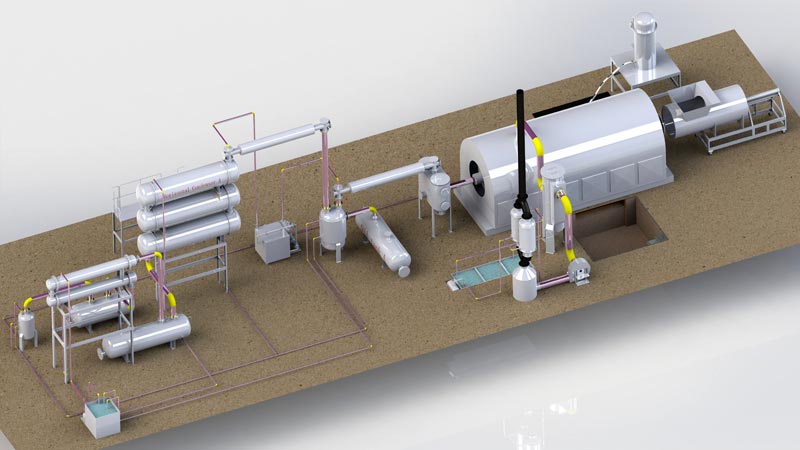

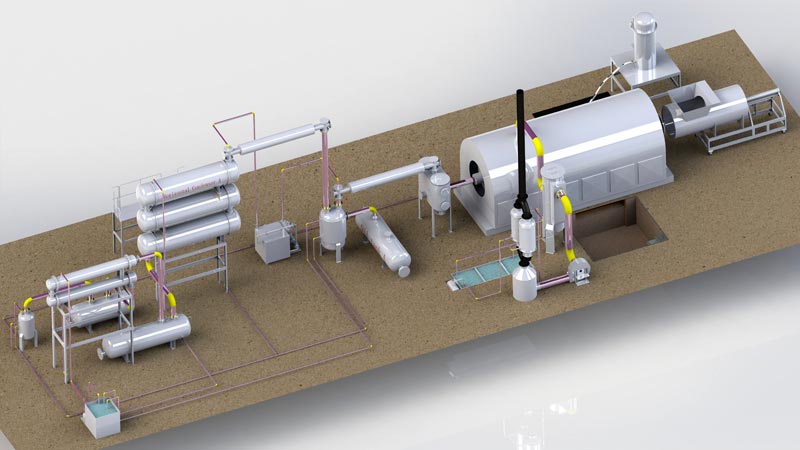

| Project ( Dimension : 6.6 *2.6m) | |

|---|---|

| Equipment | Specification |

| Equipment Model | AZ-150 |

| Material | Plastic (Waste plastic) life garbage |

| Structure | Horizontal plastic revolves |

| Capacity For One Batch | About 6-7 tons wastage plastic |

| Oil Yield Plastic | 30%-35% |

| Carbon Black Plastic | 35%-40% |

| Gas | 20% - 25% |

| Work Pressure | Normal |

| Main Engine Rotation Speed | 0.4 RPM |

| Fuels Choice | Coal, Wood, Gas, Oil |

| Power | About 35 HP |

| Cooling Method | Water |

| Cooling Water Consumption(T/H) | Cyclic |

| Type Of Drive | External Annual Gear Drive |

| Heating Method | Direct |

| Type Of Installation | With Foundation |

| Operating Mode | Intermittent Operation |

| Reactor Dimension (MM) (Long*Diameter) | 6600*2600 |

| Reactor Weight | About 28000 Kg. |

| Total Weight | About 38 MT |

| Particular | Investment |

|---|---|

| Building and land (1500sq.meters with 600sq.meters shade) | Depend on the area |

| CHINESE PLANT | |

| Price of the Plant (Ex – Factory China) 7th Generation With Auto feeder ( Dimension:2.6*6.6MT) | 60,000 USD |

| Price of the Plant (Ex– Factory China) 7th Generation Without Auto feeder ( Dimension:2.6*6.6MT) | 55,000 USD |

| Custom Duty 26%, Freight, Container Clearing Charges, Transportation Extra. | |

| This does not include the rate of interest on capital investment. | |

| Sr. No | Product | Output (%) | Output (Ton) | Price Per ton. | Total Income |

|---|---|---|---|---|---|

| 1 | Carbon Black | 35.00% | 630 | 1000 | 6,30,000 |

| 2 | Furnace oil | 30.00% | 540 | 40000 | 2,16,00,000 |

| 3 | Gas | 25.00% | 450 | --- | 0 |

| Total (A) | 2,22,30,000 | ||||

| Sr. No | Particular | Quantity | Price | Total Cost |

|---|---|---|---|---|

| 1 | Waste Plastic | 1800 | 7000 | 1,26,00,000 |

| 2 | Salary & Wages | 9*12 Month | 10000 | 10,80,000 |

| 3 | Fuel (For Initial Use) | 300 | 6000 | 18,00,000 |

| 4 | Electricity + Water | --- | -- | 8,20,000 |

| 5 | Misc. Expense (Bag Packing, Repairing, Renovation) | --- | -- | 9,50,000 |

| Total (B) | 1,72,50,000 | |||

| Profit (Earnings – Expenses) (A-B) | 49,80,000 | |||