Company Information

Ask for more detail from the seller

Contact Supplier

| Weight | |

Specific sheet | 190 ± 20g under ISO 3801 (equivalent to min 170 to 210 gsm max) |

without bands weight |

|

Complete sheet with | Plain sheet specific weight plus 10% additional weight for |

bands weight | reinforcement bands under ISO 3801 |

Total weight | From min 187 to 231 gsm. Specific weight of bands from min 150 to |

| 200 gsm max. |

| Materials | |

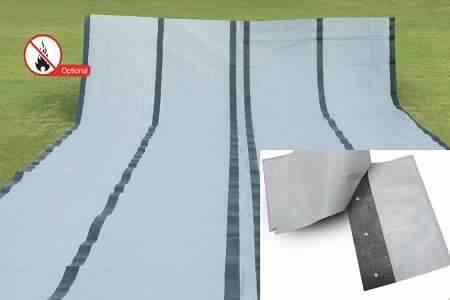

Sheet | Woven HDPE black fibers fabric, double-side lamination with LDPE coating, reinforced with 6 bands of 75 mm width woven black HDPE fibers fabric |

| and coated outside. |

| Pre-punched 8mm holes on the 2 side bands at 0.1m +/-10% intervals, positioned in the Centre of the bands (only the reinforcement bands are pre- |

| punched, not the tarpaulin itself). |

Tensile strength | Min 500N, 15-25% elongation in warp and weft in plain sheet under ISO 1421-1 |

UV resistance | After 1500 hours UV under ASTM G53/94 (UVB 313 nm peak) minimum 80% of original value of the actual product and not less than 475N |

Reinforcement | Min 700N as per ISO 1421-1, pulling lengthwise in a pre-punched 8mm hole with a hook of 8 mm wire diameter, at 200mm from the end of the band. UV |

bands | resistance 80% of original value and not less than 665N. |

Welding | Only 1 is allowed, lengthwise. The tarpaulin tensile strength crossways at the place of welding under ISO 1421-1 minimum 50% of original value and not |

| less than 400N |