Listing ID #3033392

Company Information

Ask for more detail from the seller

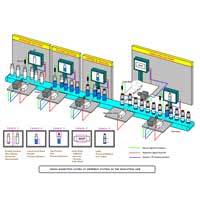

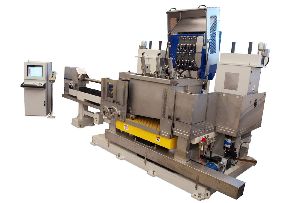

Contact SupplierFully automatic 60 to 300 Channels system (depending on the plate width and area to be tested) for 100% coverage of the plate width has been developed. It is fully automatic, state of the art, computer based system generating C-Scan type report. Mechanical system consists of Gantry arm, Client computer, Vertical drive system, Tracking structure pneumatic system, Transducer holder & Motors. The probes are placed in the probe holder and water for the coupling is fed with pump. Probe holder is designed in such as way that it ensures a small layer of water between surface of plate and probes hence problem of improper coupling is avoided. These holders have a mechanical arrangement to clamp on to the surface of the plate as soon as the plate comes below it for testing. All these mechanics are held by an over head boom or gantry. Vertical drive system is used to vary the height of the probes holders according to variations in plate thickness. The probe holders are mounted on guided pneumatic cylinders and these cylinders clamp on to the plate as soon as plate moves below it. The probe holders are connected to pneumatic cylinder via a universal joint kind of arrangement to enable probes to get aligned to the plate surface, the landing mechanics are sturdy enough to avoid bending caused due to friction between probe shoe and plate surface. The system is complete with water reservoir pumps etc. The system operates in complete automated cycle after initial settings are done for a particular plate size and the inspection is monitored by an operator in control room.