Company Information

Ask for more detail from the seller

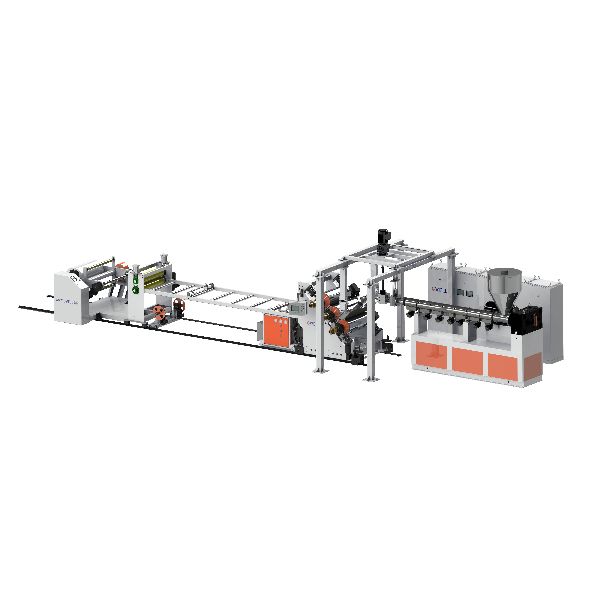

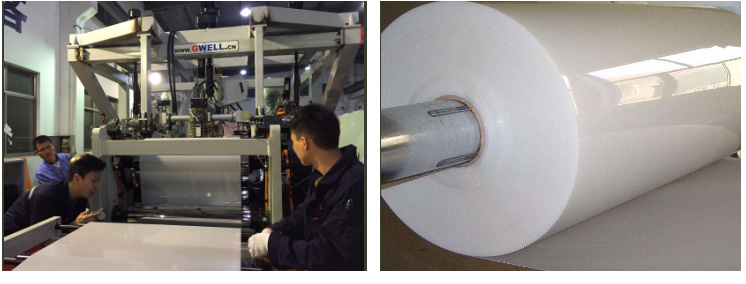

Contact Supplierpp/ps sheet extrusion production line is common for single-extruder single-layer sheet production line and double-extruder co-extrusion three-layer sheet production line. There are also multi-extruder co-extrusion multi-layer production line, which can process 7-9 layers of composite sheet at most, such as high-barrier evoh multi-layer co-extrusion production line. This type of extrusion line can process pp, ps, pe and other polyolefin materials.

gwell pp/ps sheet production line:

multi-extruder co-extrusion technology is adopted to produce multi-layer co-extrusion composite pp and ps sheet, such as aba, abcba, abcdcba and other multi-layer structure, which is widely used in heat forming, printing, hardware packaging, electronic tray, flocking, food, clothing, tools, toys, stationery pieces, decorative pieces and so on.

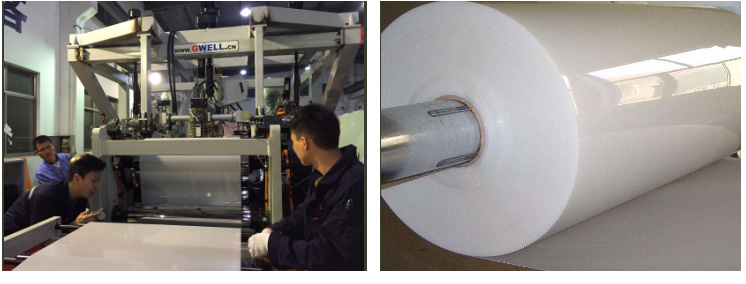

* equipped with precise distributor, evenly layered, adjustable proportion of each layer, digital precise control.

* inclined horizontal structure, easy to operate and maintain.

* roller independent power, linear speed and extruder speed synchronous closed-loop control.

* the whole machine adopts plc control to realize automatic control of parameter setting, data operation, feedback, alarm and other functions.

* gwell independently wrote the electronic control operating system

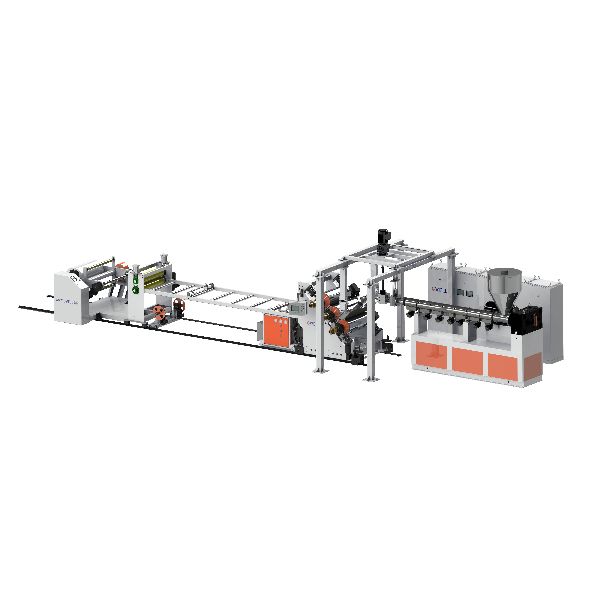

main applications of pp/ps sheet:

* pp/ps blister sheet

* pp/ps single layer sheet, pp/ps co-extruded two-color sheet, pp double-sided high-transparency sheet, etc. Sheet used in blister packaging industry.

* pp stationery sheet

* pp transparent sheet, frosted sheet (coarse sand, fine sand), two-color sheet used in stationery packaging industry sheet.

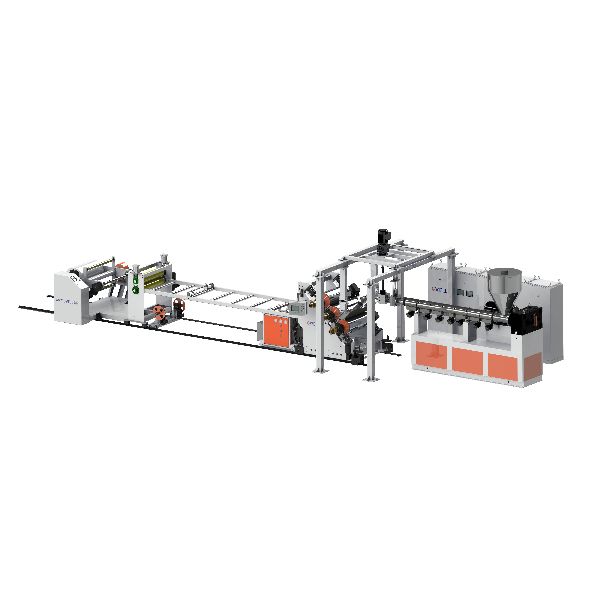

* pp foam sheet, pp foam sheet has unique advantages, pp foam sheet with density of over 0.45g/m3 has a good bending resilience, not easy to deformation, so it has a broad prospect in the field of folders; pp foam sheet with density of 0.6g/m3 has good mechanical prop