Company Information

Ask for more detail from the seller

Contact SupplierApplication & Process :

pneuCONVEYOR is a manufacturer of custom pneumatic conveying systems and support equipment for conveying, vacuum conveying, batching, and weighing materials.

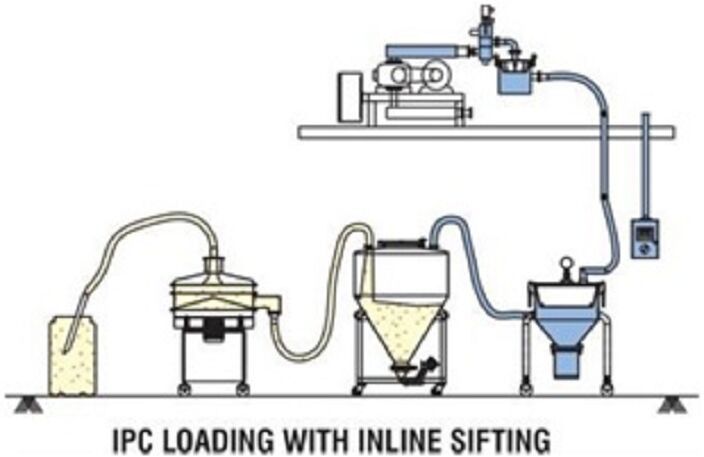

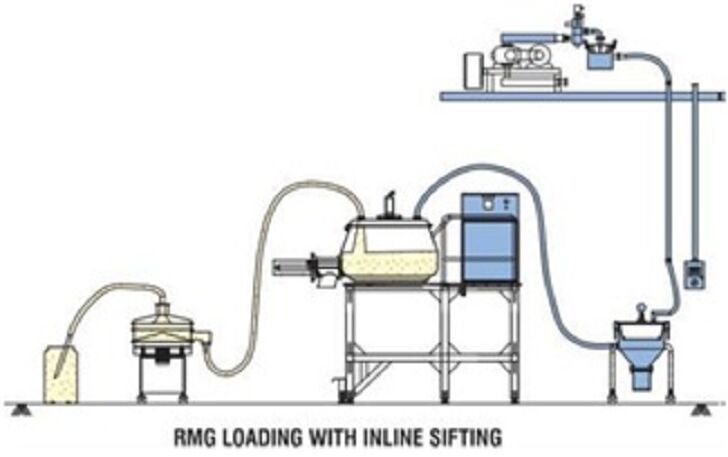

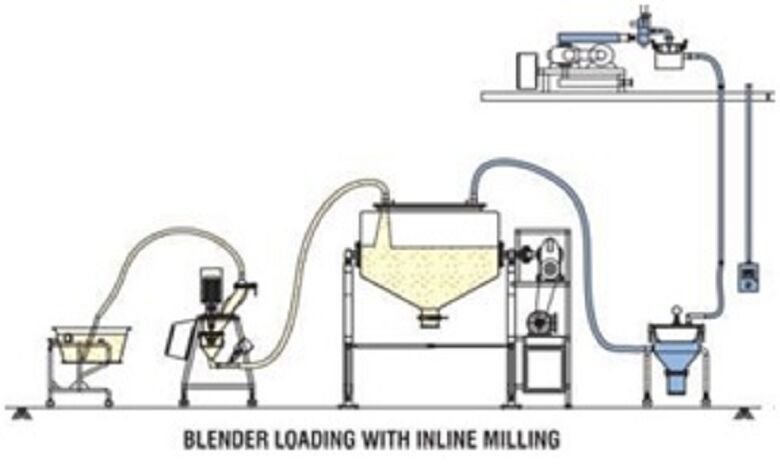

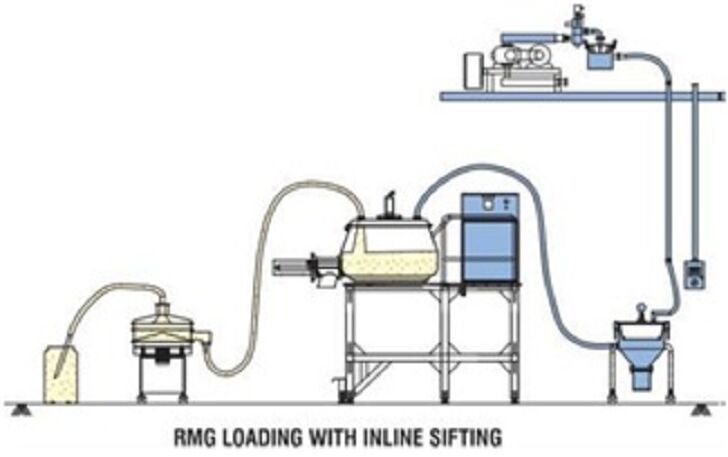

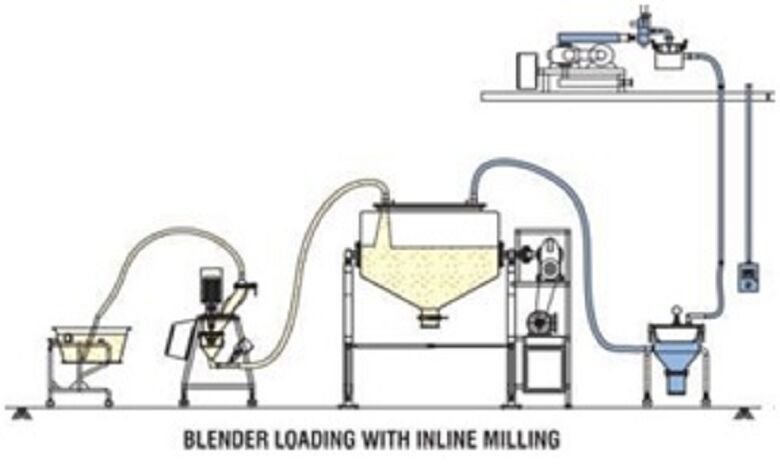

The Vacuum transfer system is unique dry material transfer system for dust free and avoid human touch. The Vacuum transfer system is used in Pharmaceutical, Food, Bulk Drug, Agro chemical, Sugar Industries and other organic & Inorganic chemicals. The system is used for inline milling, sifting, blending, loading and unloading.

The principle of Vacuum transfer system has been proven to be a better way to move many types of material and a giant step over manual handling. The technology exists for moving virtually any material that can be pulled through a hose or tube. The system is consisting of Blower, Vacuum receiver system with filter, cyclone filter and Pipe.

The Vacuum transfer system designed specifically for the direct charge loading of blenders, mixers, sifter, milling, reactors or any vessel capable of withstanding a vacuum, A Powder loader is provided for machines & vessel not capable or facilitate to create vacuum. The vacuum system can be provided mobile type with lifting provision to move one room to another room for loading and unloading any machine.

Preferred applications: For reliable feeding of free-flowing powders and granular bulk material to processing machines in the Pharmaceutical, Bulk drug, food, plastic and chemical industry.

The material can be picked up from e.g. sacks, drums, container or silos. The type pC- receivers are used as individual receivers, with a separate blower each, in discontinuous vacuum, low-velocity vacuum and dense-phase conveying systems. They are mounted on the batch hopper of the processing machines where they serve for separating of the bulk materials.

Special advantages:

Typical advantages of conveying system:

SUITABILITY : Emptying or filling process equipment (reactors, dryers, blenders / mixers / centrifuges, etc.).

DUST FREE : Material can be drawn directly from drums, Bags, storage containers, process.vessels- no messy dumping or manhandling. Charging of powder directly into closed vessels, including those under vacuum or pressure, preventing the formation of dust and the introduction of oxygen. Charging also possible in the presence of solvents.

System can be completely sealed, any leakage in system will be inward- no noxious or hazardous materials discharged into work area.

VERSATILE : Conveying lines can be routed between floors, through partitions, aroundmachinery- can easily be re-routed to accommodate process modifications. Adaptable to many process operations- easily integrated & automated.

SANITARY : Materials of construction & finishes selected for the products being handled. Easily disassembled modular design facilities cleaning.

PHARMACEUTICAL APPICATION: Inline Sifting/ RMG Loading/ Inline Milling/ Blender Charging/ IPC Loading/ Tablet Press Loading/ Auto Coater Loading/ Unloading/ Blister/ Strip Pack Loading/ Tablet-Capsule Transferring/ Auto. Drum/Bag Filling & weighing system / Other application can be designed on demand.

FOOD APPLICATION: Flour/ Granulated Sugar/ Dextrose/ Coffee/ Tea/ Milk Powder/ Peanuts/ Salt & Many more.

CHEMICAL APPLICATION : Talcum Powder/ Aerosol/ Sodium Sulphate/ Gelatin & many more

PLASTIC APPLICATION : P E Granules/ P V C Powder/ PVC Blend/ L.D.P.E./ Calcium