Company Information

Ask for more detail from the seller

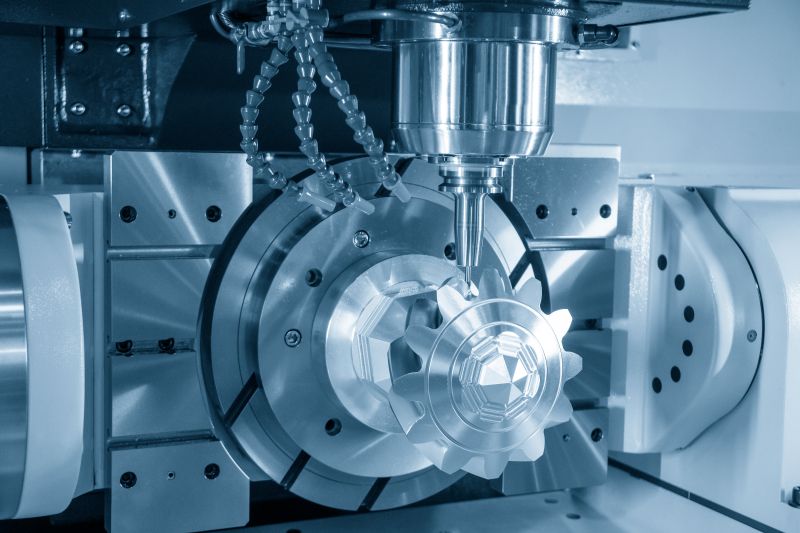

Contact SupplierProcess Overview – It is a process that creates a desired shape and size by removing the unwanted material from a larger piece of metal i.e Subtractive Manufacturing. A plethora of machining options are available depending on the part geometry, profile to be achieved, GD & T requirements, surface finish, throughput etc. CNC (Computer Numerical Controlled) machining is a widely used manufacturing process that uses automated high-speed cutting tools to form a particular feature from metal or plastic. CNCs are generally classified as 3-axis, 4-axis and 5-axis based on the movement of part and tooling along the axis. Different machines have different working mechanisms such as : a) workpiece securely clamped while the tool moves b) tool may remain in place while the workpiece moves c) both the cutting tool and workpiece move together.

Capabilities

Prototype to high volume production of up to thousands of parts per year based on part configuration

CNC machining of parts weighing up to 10 Tonnes

CNC machining of parts measuring up to 1000mm Dia and 4000mm Length

Small and big sized VMC machines up to X axis – 4000mm, Y axis – 2000mm and Z axis – 1000mm

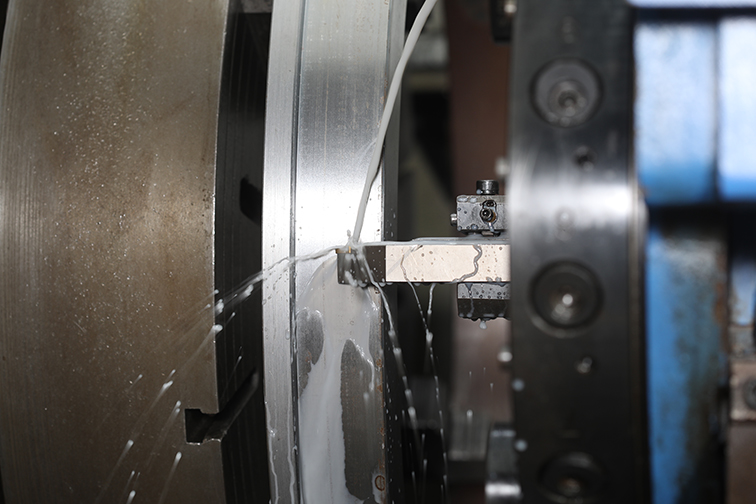

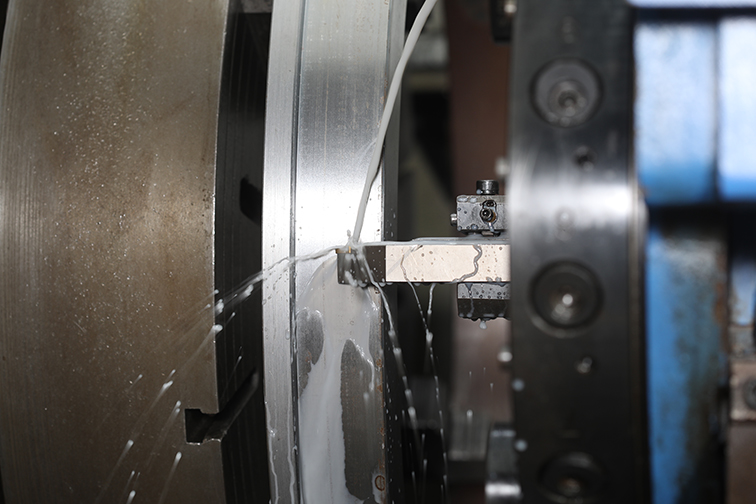

Cylindrical Grinding of parts up to 800mm Dia and 6000mm Length

Conventional turning of parts up to 1500mm Dia and 6000mm Length

Supporting machining operations such as Cutting, Deep hole drilling, Milling, Boring, Broaching, Gear hobbing, Surface grinding etc.

Machining of wide variety of material grades such as Carbon steel, Alloy steel, Tool steel, Non-ferrous alloys, and Superalloys

Machining of castings and forgings of small to large sized parts

Tight tolerance of machined parts up to ± 0.005mm

Post-machining surface finishing operations such as ID and OD polishing, Superfinishing, Honing etc.

Surface treatment processes such as plating, anodizing, phosphating, blackodizing, thermal spray coating, slurry coating, polymer painting etc.

CMM inspection for part validation and approval of machined parts

ERP notified calibration control system for measuring/monitoring instruments and machines

In-house lab tests carried out for raw material verification at production site, certified to NABL standards

Complete NDT testing of parts for defect analysis pre and post machining as per international standards

Customer appointed third party inspection and verification allowed

Manufacturing facility certified to IATF 16949 and AS 9100 Rev.D Quality Management System

Implementation of Lean Six Sigma tools for better quality control, process control, part traceability and documentation

Industry 4.0 integrated manufacturing facilities

Application and Benefits

We supply machined components to almost all industry sectors in batch and mass production quantities. The design and functional characteristics of the part are fixed based on its end application. Selection of the material is done to sustain the working environment and machined to accurate dimensions to ensure proper fit and assembly.

Usually, Aerospace engine parts are made from Titanium, Tantalum and Nickel based alloys which exhibit high strength, low weight and high temperature fatigue resistance

Similarly, parts used in Oil & Gas and Power Generation sectors are made from Nickel, Chrome and Cobalt based alloy steels which exhibit high wear and corrosion resistance

Few key benefits of machining include :

Rapid Tooling – A variety of materials can be machined to achieve accurate dimensions for making fixtures and molds.

Rapid Prototyping – Flexibility of manufacturing small scale prototypes saves a lot of time, money and effort and enables to conduct a detailed part validation and risk assessment

Production – Reliability and Repeatability of machining can be ensured by application of advanced process control techniques which enables mass production

Customization – Wide range of advanced manufacturing techniques increases the scope of customization for new part development