Company Information

Ask for more detail from the seller

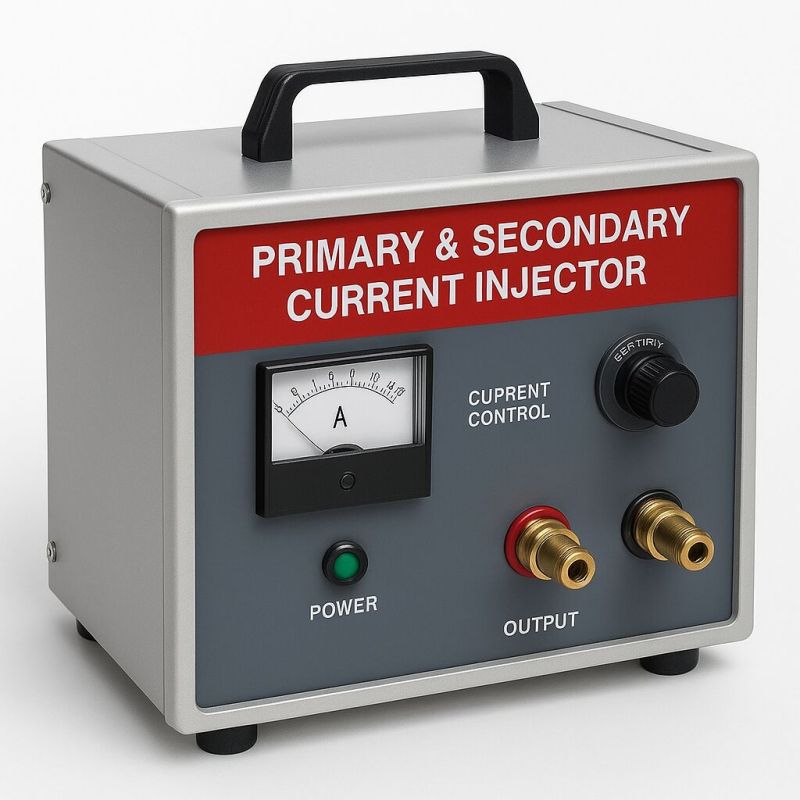

Contact SupplierPrimary & Secondary Current Injector – Reliable Testing Solution for Electrical Systems

The Primary & Secondary Current Injector is a highly reliable and efficient testing instrument designed for verifying the performance and accuracy of electrical equipment such as protective relays, current transformers (CTs), potential transformers (PTs), and circuit breakers. Widely used in power plants, substations, manufacturing industries, and testing laboratories, this equipment ensures the safety, reliability, and smooth operation of electrical protection systems.

Introduction

In any power system, relays and circuit breakers play a vital role in protecting equipment from electrical faults. However, their performance needs to be regularly tested and calibrated to ensure accurate functioning during fault conditions. This is where the Primary & Secondary Current Injector comes into play. It provides the required high current (primary injection) and low current (secondary injection) to simulate fault conditions and verify the response of protection devices.

Working Principle

The equipment operates by injecting a controlled amount of current into the system.

Primary Injection Testing: Used for testing CTs, bus bars, and circuit breakers by injecting high currents (up to several thousand Amperes).

Secondary Injection Testing: Used for testing protective relays and CT secondary circuits by injecting low-level currents to check relay settings and tripping accuracy.

This dual functionality makes the device highly versatile and essential for electrical maintenance.

Key Features

High Accuracy: Provides precise current output for accurate testing.

Wide Range: Available in various current ratings from 1A to 5000A depending on customer requirements.

Portable & User-Friendly Design: Available in compact or trolley-mounted models for easy mobility.

Multiple Protection Options: Built-in safety features against overload, short circuit, and overheating.

Digital / Analog Display: Clear measurement of current and voltage outputs.

Durability: Rugged construction with high-quality components ensuring long operational life.

Applications

Testing and calibration of protective relays.

Current Transformer (CT) testing for accuracy verification.

Circuit breaker testing to ensure proper fault-clearing operation.

Simulation of fault conditions in substations.

Used in power plants, industrial facilities, service centers, and laboratories.

Technical Specifications (Typical Models)

Input Supply: 220V / 415V AC, 50Hz.

Output Current: Up to 5000A (depending on model).

Power Capacity: 500 VA to 5 kVA.

Automation Grade: Manual / Semi-Automatic / Automatic.

Cooling System: Air / Oil cooled (as per rating).

Advantages

Ensures safety and reliability of electrical systems.

Reduces risk of equipment failure during fault conditions.

Helps utilities comply with international testing standards.

Time-saving and cost-effective testing solution.

Conclusion

The Primary & Secondary Current Injector is an indispensable tool for any organization dealing with electrical testing and maintenance. Its ability to perform both high-current primary injection and precise secondary injection makes it a complete solution for testing relays, CTs, and circuit breakers. With its robust design, high accuracy, and user-friendly features, it ensures dependable performance and enhances the safety and reliability of power systems.