Company Information

Ask for more detail from the seller

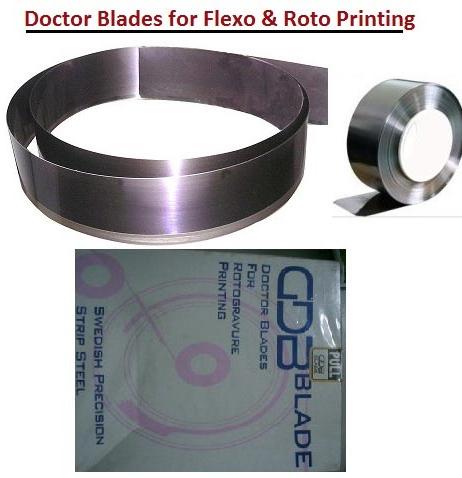

Contact SupplierOur Printing Doctor Blades are available in different widths and thicknesses to suit the specific requirements of the clients. These Printing Doctor Blades are specially designed for Rotogravure, Flexographic & Pad printing. Printing Doctor Blades are manufactured from highly refined strip steel and are finished with an extra smooth edge ensuring that the blades perform a clean wiping action on the gravure cylinder / anilox roller immediately on start-up. Our Printing Doctor Blades are used for Rotogravure & Flexographic printing, as well as for coating applications. Printing Doctor Blades are wiping blades used to wipe excess ink in the Flexographic or Rotogravure Printing and coating processes. It is an essential part of the process for achieving top quality printing.

Further, our Printing Doctor Blades increase productivity, improve quality and reduce wastage or rejections. Printing Doctor Blades can be used to print coat paper, films such as PET, BOPP, PVC etc., and foils used in packaging, labeling, publication and corrugation. Lamella edge is the most commonly used edge configuration preferred by customers. The unique shape of the lamella ensures that a constant contact area with the cylinder is maintained throughout the life of the blade, resulting in uniform printing during the print run. Thus, no re-sharpening is required. The wiping action of our Printing Doctor Blades can directly affect the quality of printing, coating, etc. Our Printing Doctor Blades provide high quality, error-free & cost effective printing & coating operation.

Advantages :

Applications : Rotogravure and Flexographic printing with solvent based inks and coatings

Specifications :