Company Information

Ask for more detail from the seller

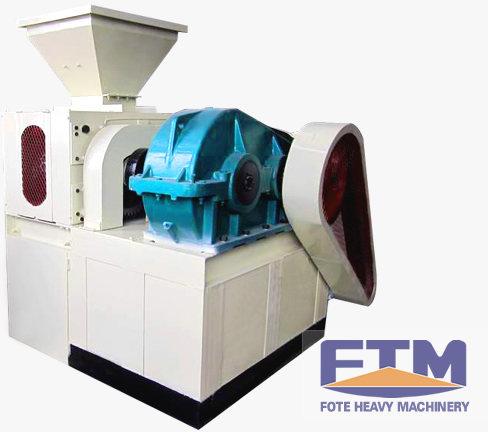

Contact SupplierThe charcoal briquette machine is used to making balls directly from the crushed materials, without adding water. Its purpose is to reduce the dust, the control capacity, return to use, facilitate transportation. Charcoal briquette machine can be used to compress the pulverized coal, iron powder, coking coal, aluminum powder, scrap iron and tin oxide, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke, waste residue etc. It is widely used in refractories, power plant, metallurgy, chemical, energy, transportation, heating, etc. The products that molded at last are energy conservation and environmental protection, easy to transport and greatly improve the utilization rate of the waste.it has great economy and social benefit.

Charcoal briquette machine

working process of hot sale charcoal briquette machinehot selling productive charcoal briquette machine

1. Preparing raw materials

when you are collecting raw materials, various stuff are available. For example, burnt charcoal,rice husk, com cob,maise stalk,waste cartoon,wood pieces,empty fruit brunches, tree trimmings and so on. There is no doubt that it is an effective and environment-friendly act.

2. Crushing or crumbing

generally speaking, it is not advisable to briquette raw materials directly. Crushing or crumbing is necessary. After this step,raw materials can be formed into pellets so that it is convenient to be manufactured further. With a simple and novel design,our crushing machine is composed of two main sections, which include chassis and smash parts. For the former, the channel beam can stabilize foundation and provide supports for its overhead units. While for the latter,motor drives the main shaft.when the crush is finished,you can easily proceed the next stage.