Company Information

Ask for more detail from the seller

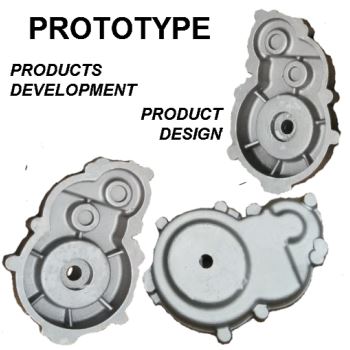

Contact SupplierWith fast manufacturing of prototypes and small series, we offer you the possibility to shorten your development process. We can confidently provide the complete solution for all your prototyping needs. We can help find a solution to get your parts from development stage through to production in the quickest most efficient way whilst still to the highest quality.

The precision casting process is suitable for the production of metal prototypes with a similar quality like die cast components or as well for thin-walled components. In order to most effectively validate your creation, pay close attention to these three key elements: functionality, manufacturability and viability. This will ensure the best results and help you to develop further. Adjustments in design, materials, size, shape, assembly, color, manufacturability and strength can be made following the results of your engineering prototype testing and analysis. Technologies frequently used for prototype CNC Machining, Sand Casting, vaccum casting, 3D printer etc.

Growing number of clients are taking advantage of our full range of reverse engineering expertise which extends much further than simply the production of the pattern to include the actual casting, machining and shipping. The turnkey solution has also proved to be extremely attractive to clients in the prototype stage and by working closely together from the initial stage of design, our experts are able to save cost, avoid over engineering and ultimately reducing lead time from prototype to production.

Our experience allows us to take on all stages of product and tooling development. We can take a napkin sketch and turn it into a production reality, or aid in recommendations for mold-ability and ease of manufacturing.

Prototypes up to small batch or low volume by casting technology.

We offers following types of prototype services to aid in the process of proper fit and function before finalizing your design and beginning the tooling phase.

1.CONCEPT MODELS PROTOTYPE

2.DESIGN & ENGINEERING VALIDATATION PROTOTYPE

3.FUNCTIONAL & ENGINEERING PROTOTYPE

USES OF PROTOTYPES

Customer Evaluation

Visual models

Concept models

Design verification

Fitment check

Assembly test

Functional test

Life test

MATERIALS FOR PROTOTYPES

Metals Prototypes

Aluminum

Cast steel

Cast iron,

S.G.Iron

Stainless Steel

Sheet metal.

Brass

Copper

NON-Metals Prototypes

ABS

PC / Polycarbonate

PMMA / Acrylic

PA/Nylon

PP / Polypropylene

Epoxy board

RUBBER

APPLICATION INDUSTRIES

AUTOMOBILE INDUSTRIES

COMMERCIAL PRODUCT INDUSTRIES

AERO SPACE

POWER INDUSTRIES

R & D DEVISIONS

MEDICAL EQUIPMENT INDUSTRIES