Company Information

Ask for more detail from the seller

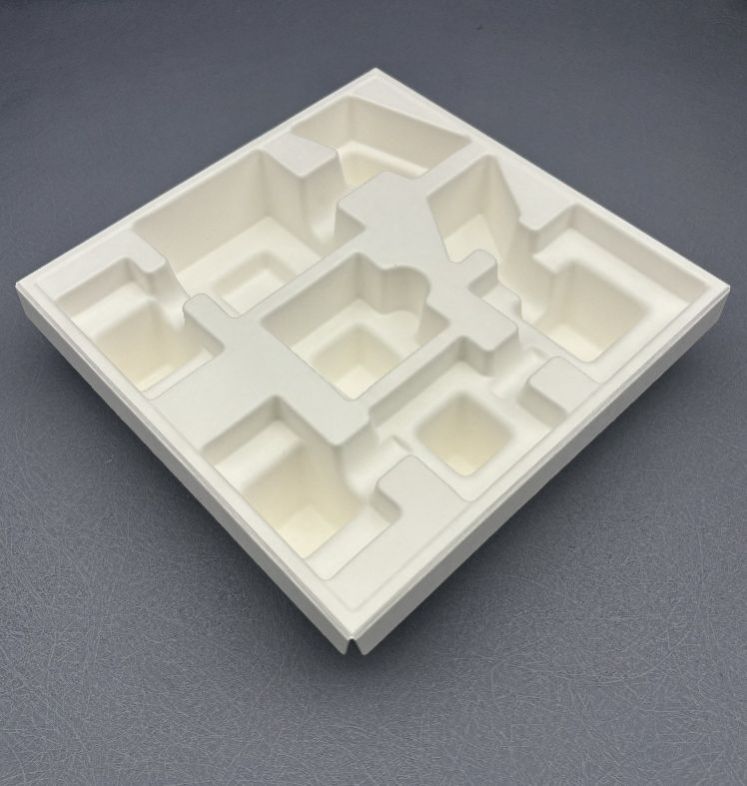

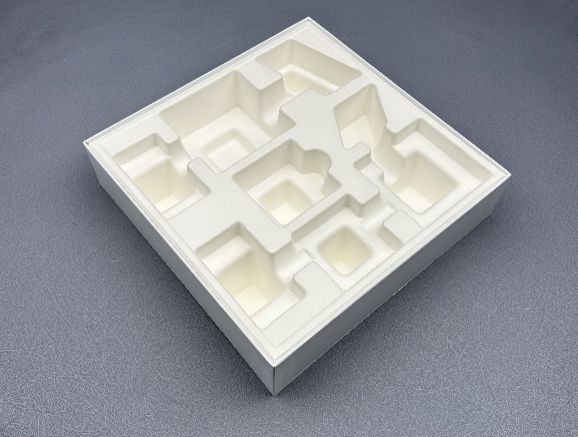

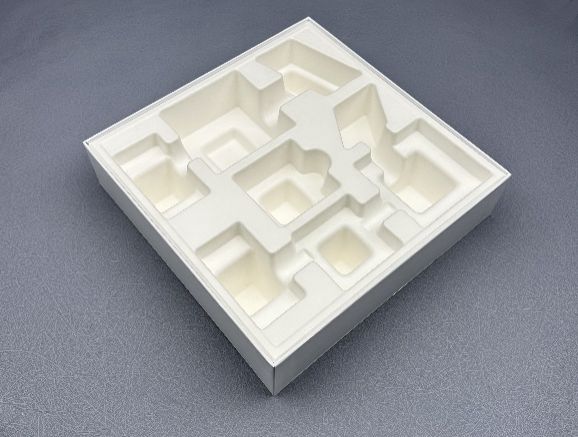

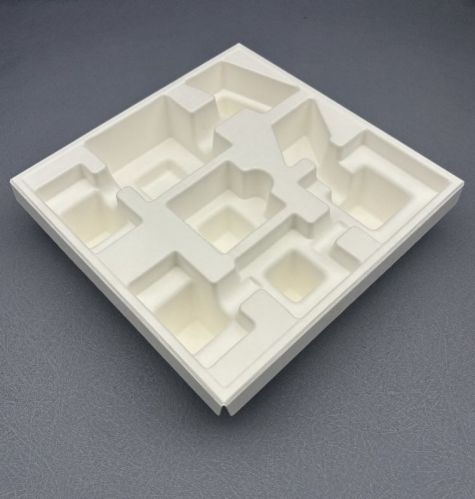

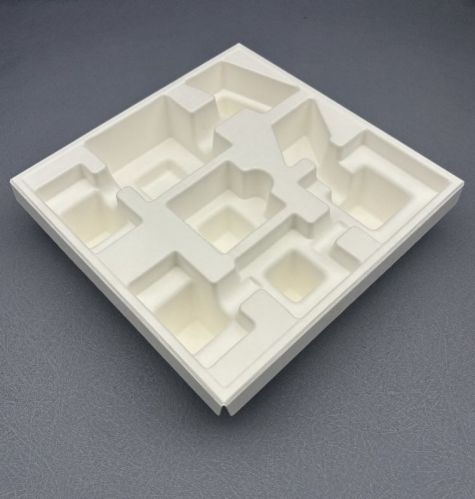

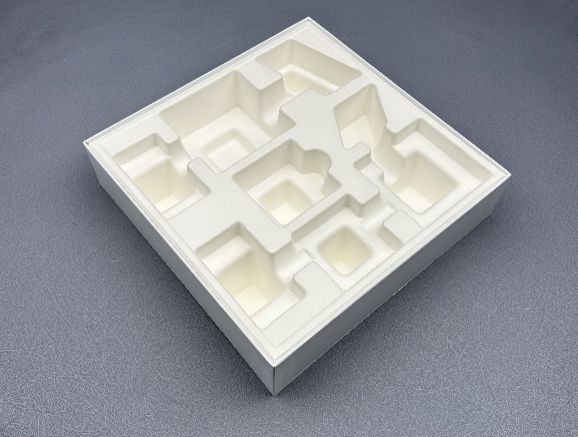

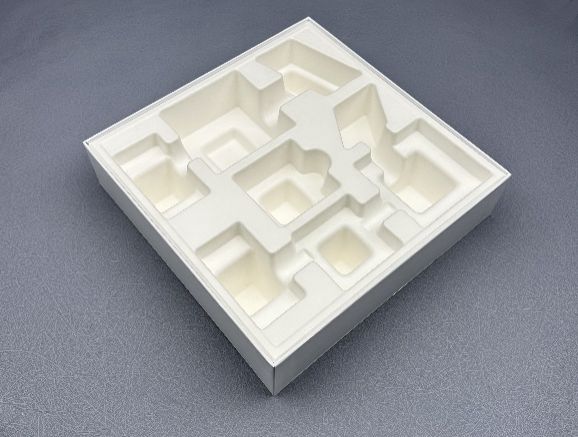

Contact SupplierPulp Molding: The Eco-Friendly, Sustainable Solution for Packaging and Manufacturing Pulp molding is an eco-friendly, sustainable manufacturing process that utilizes recycled paper or plant fibers to create durable, biodegradable products. This innovative technology is widely used in various industries, including packaging, food containers, electronics protection, and industrial parts manufacturing. As a greener alternative to plastic and foam, pulp molding offers a solution that not only reduces waste but also provides high-performance products that are 100% biodegradable. With increasing global awareness about environmental impact and sustainability, pulp molding is becoming the preferred choice for environmentally-conscious businesses. Why Choose Pulp Molding? One of the main benefits of pulp molding is its eco-friendly nature. By using recycled paper and natural fibers, the process creates products that are fully biodegradable, unlike plastic or foam alternatives. The use of recycled materials reduces the need for virgin resources, contributing to a more sustainable manufacturing cycle. Products made from pulp molding break down naturally over time, leaving no harmful waste in landfills or oceans, making them an ideal choice for eco-conscious consumers and industries. The Pulp Molding Process The pulp molding process begins by mixing water, recycled paper, and sometimes plant fibers to create a pulp mixture. This pulp is then poured into specially designed molds that shape the material into the desired product form. Once the mold is filled, a vacuum system is used to remove excess water, and the product is left to dry. This results in a lightweight, strong, and stable product that can be used for various applications, from packaging to protective inserts for electronic products. Density Control in Pulp Molding An essential factor in pulp molding is the control of product density. Typically, the density is maintained at approximately 3% to ensure optimal product performance. The density of a molded pulp product determines its durability, strength, and overall quality. By carefully managing the pulp density, manufacturers can ensure the final product is neither too heavy nor too fragile. This control helps maintain a balance between the material's strength and its weight, making it suitable for diverse applications while retaining eco-friendly characteristics. Customization and Flexibility of Pulp Molding Pulp molding offers remarkable flexibility in terms of design and customization. Manufacturers can create custom molds to produce products with unique shapes and sizes tailored to specific needs. Whether it’s for protective packaging, food containers, or industrial components, pulp molding provides the versatility to meet diverse requirements. The process also allows for intricate detailing, making it possible to manufacture custom shapes, logos, and designs that enhance branding and functionality. Pulp Molding Applications Across Industries Pulp molding has a broad range of applications across various industries. In the packaging industry, it is commonly used for creating protective packaging for fragile items, such as electronics, glassware, and pharmaceuticals. In the food industry, pulp molding is used to produce disposable, biodegradable food containers, plates, and trays. Additionally, many industrial sectors rely on pulp molding for creating components that need to be lightweight yet durable, such as inserts, dividers, and parts that require specific cushioning. Sustainability and Environmental Impact of Pulp Molding One of the most significant advantages of pulp molding is its sustainability. As concerns about plastic pollution grow, many companies are seeking alternatives that minimize environmental harm. Pulp molding products are not only biodegradable but also made from renewable resources, making them a sustainable choice. By opting for pulp molding, businesses contribute to reducing plastic waste and promoting