Company Information

Ask for more detail from the seller

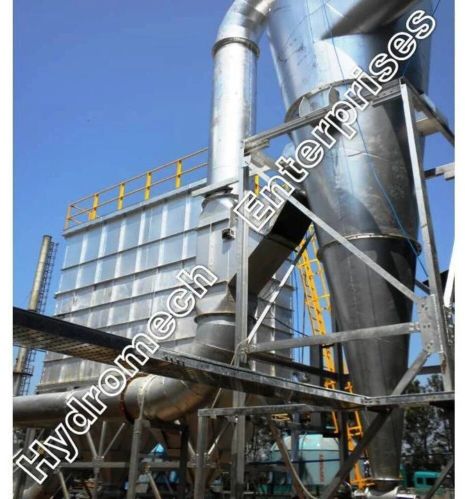

Contact SupplierA Pulse Jet Dust Collection System is a high-efficiency filtration system engineered to remove fine and heavy dust particles from industrial airstreams using compressed air cleaning technology. Widely used in industries with continuous or high-volume dust loads, pulse jet systems ensure uninterrupted airflow, minimal maintenance, and compliance with air quality regulations. System Description: Pulse jet dust collectors operate using filter bags or cartridges that trap airborne particles. A rapid pulse of compressed air is periodically released to clean the filters by dislodging accumulated dust, which then falls into a collection hopper. 1. Dust Collector Housing Heavy-duty steel or stainless-steel construction Designed to withstand negative pressure and high dust volumes Available in vertical or horizontal configurations 2. Filter Media Filter Bags (woven or nonwoven fabric) or Pleated Cartridges Surface treatments available: PTFE coating, anti-static, fire-retardant, hydrophobic High-efficiency filtration for particles as small as 0.3 microns 3. Pulse Jet Cleaning System Uses compressed air pulses released via solenoid valves Cleans filters on-line without stopping the airflow Ensures consistent suction and extends filter life ✅ 4. Hopper and Dust Discharge System Collects dislodged dust for safe disposal or recycling Options include manual trays, rotary airlocks, or screw conveyors ✅ 5. Control System Digital controller manages pulse timing and duration Optional differential pressure sensors for automatic pulse control Can integrate with plant-wide PLC or SCADA systems