Listing ID #4852340

Company Information

Ask for more detail from the seller

Contact Supplier

|

|

|

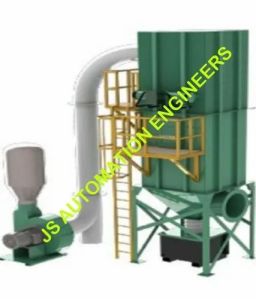

Normally closed solenoid valve actuated by signal from remote sequence timer. Pressure got decrease in the tube between solenoid and right angle diaphragm valve after solenoid valve open. It causes diaphragm valve to open permits a momentary air jet from air supply. High velocity air through pipe comes out from nozzles inserted inside the venture. Pressurized and high velocity airflow inside the filter begs causes controlled inflation of bag. So, that Accumulated dust is dislodge and collected in the conical hopper. Clean air comes outside from bags towards plenum. Sequential timer can operates on time sequence or by measuring pressure difference. Separate line of blow tubes and valves continuously clean each raw of bag by automatic operation. Filtration efficiency depends on type of filter bag, efficiency, frequency of intensive cleaning. Filtration cycle should select practically, so that most of filtration area is available clean most off time. Design of PULSE JET DUST COLLECTOR Tridev Pulse Jet Dust Collector is having many filter bags. Filter bags and other assembly enclosed in a metal housing. It consist plenum at top, beg housing at middle and material collection at bottom section. Plenum section is holding air pipes/orifice nozzle and supports air receiver tank, blow tubes and solenoid valve. Beg housing is separated from plenum by tube sheet. Beg assembly stays inside beg housing which are clamped with ventures, beg retainer, filter begs and clamps on tubes sheet. Material collection hopper at bottom is with inlet, diffuses and outlet. Sequential timer, air pressure gauge, and blower fitted on frame. Rotary air lock valve need s mount at outlet of PJDC to discharge powder and prevent air leakage. Advantages of Tridev PULSE JET DUST COLLECTOR 1. Improve product quality getting deteriorate due to system air temperature. 2. It clean dusty air generated/used inside system and Improve exhaust air quality. 3. Collect valuable material which is getting escaped with air. 4. Control system air pressure and improve machine efficiency & energy consumption. 5. Control system temperature which is getting increased due to filter bag blockage. 6. Eliminates manual cleaning of filter bags. 7. Eliminates human intervention and error. 8. Improve workshop atmosphere by collecting dusty air at inlet/outlet of machines. |