Company Information

Ask for more detail from the seller

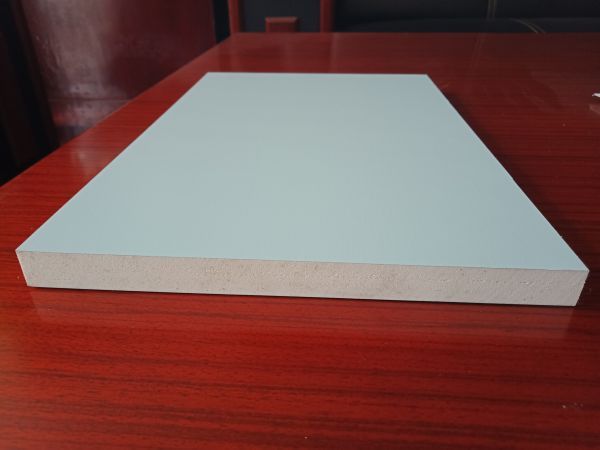

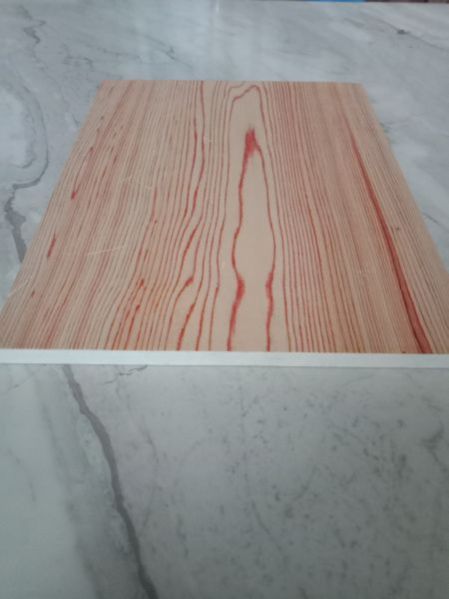

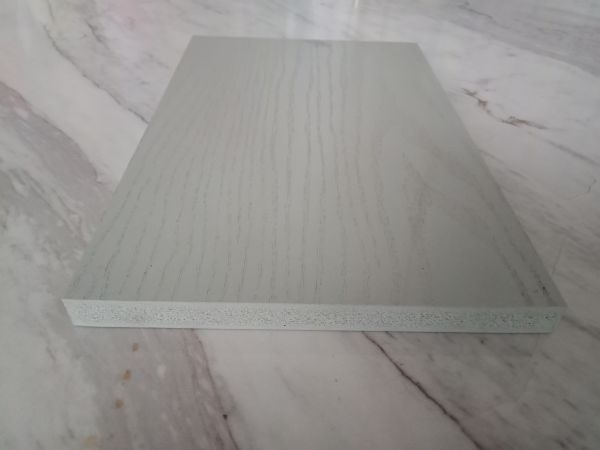

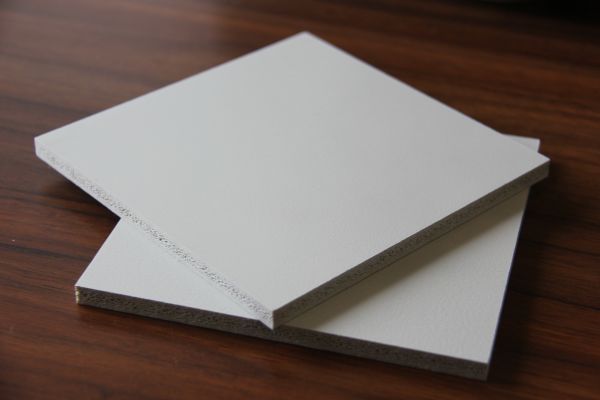

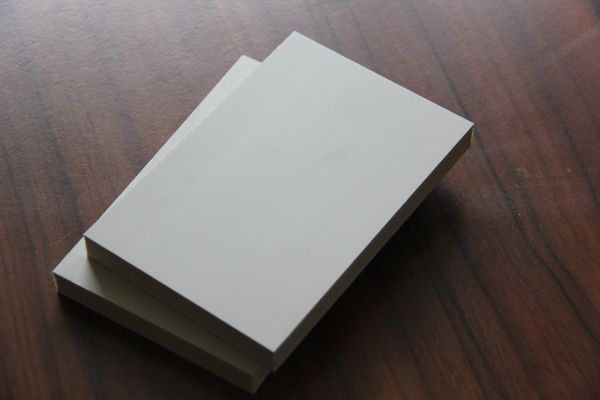

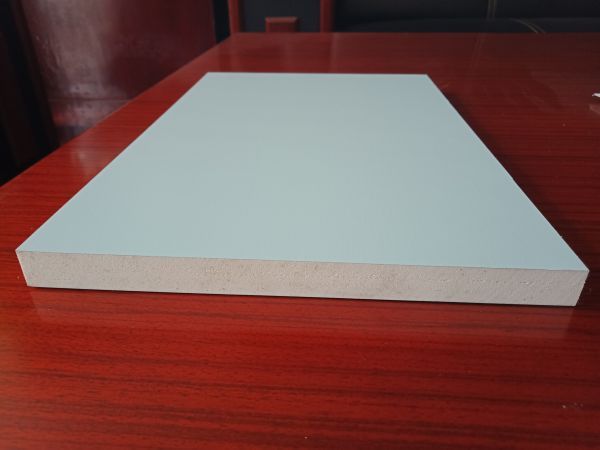

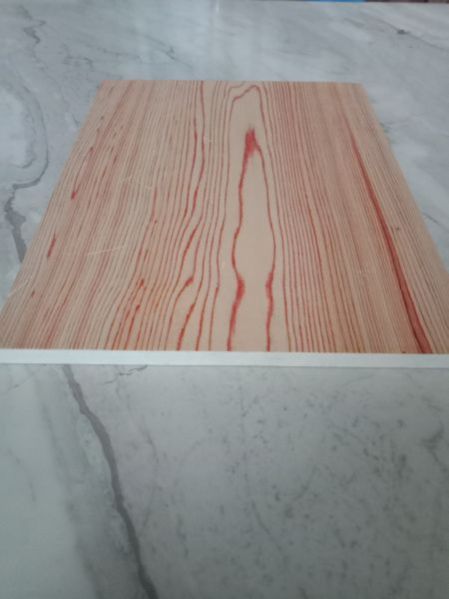

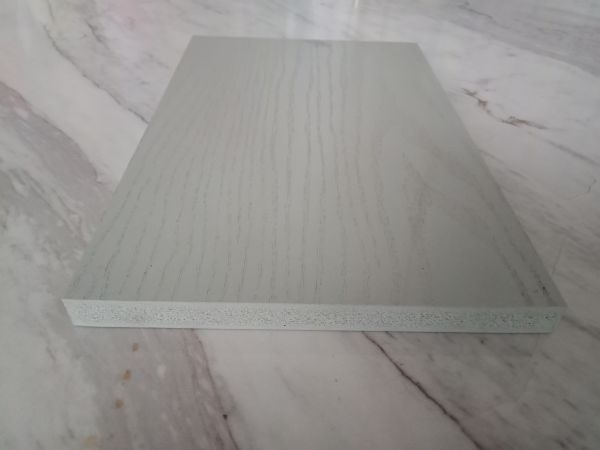

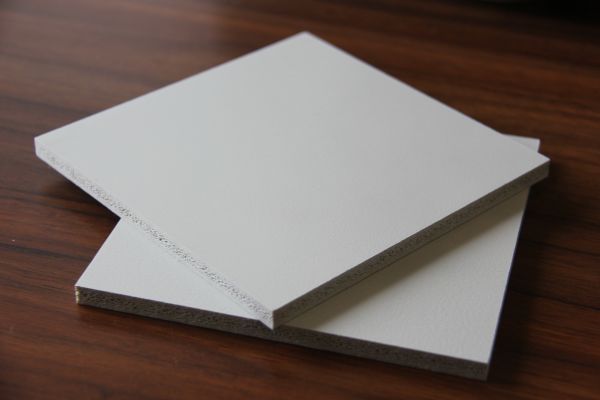

Contact SupplierZhongYang DeXin PVC Celuka Foam sheet owes its unique product properties to the combination of a solid topcoat and acellular core, the surface has a solid, smooth outer skin that gives the formwork a silk-glossy finish,and has the following unique specifications :

Excellent Properties :

Key Benefits :

Advantages of PVC Celuka Foam Sheet :

DeXin integral foam sheet is fabricated with Krauss Maffei's technology, which makes its surface smooth & bright, no deformation, high hardness & intensity, aging resistance, good plasticity, strong stability , as makes it perfect for waterproof bathroom ark and can be recycled for more than 20 times during usage.

| Sr. No. | Item and units | Standard requests | Results | Conclusion | |

| 1 | Size Deviation (mm) | Thickness | 15±0.4 | 14.84 | OK |

| Length | 2440(-2~0) | 2440 | OK | ||

| Width | 1220(-2~0) | 1219 | OK | ||

| Right angle(mm/m) | ≦1 | 0 | OK | ||

| Angularity(%) | ≦0.5 | 0.1 | OK | ||

| Diagonal line length | ≦2 | 1 | OK | ||

| 2 | Appearance Status | Surface | Flat and smooth,without crack and scratch, Without palpable impurity and non-dispersive accessory | OK | |

| Flow mark and stripe | Palpable flow mark and stripe shouldn’t be not allowed | ||||

| Groove | Two grooves with the depth of no more than the thickness limit deviation and the width of no more than 10mm are allowed within the scope of no more than one fifth of sheet width from the longitudinal edge of the sheet | ||||

| Concave-Convex | Less than 1mm bump allowed;per square meter the quantity of less than 10x10mm minor bumps should less than five and dispersive | ||||

| Material shortage mark | Palpable material shortage mark not allowed | ||||

| Scratch mark | Slightly felt scratch mark allowed and should not be netted | ||||

| 3 | Water absorption(%) | ≦0.5 | 0.5 | OK | |

| 4 | Shore hardness(Surface),HD | ≧58 | 78 | OK | |

| 5 | Impact strength notch charpy(kJ/2) | ≧14 | 15.9 | OK | |

| 6 | Flexural strength(MPa) | ≧24 | 28.6 | OK | |

| 7 | Flexural modulus of elasticity(MPa) | ≧1200 | 1767 | OK | |

| 8 | Vicat softening point(℃) | ≧75 | 80.3 | OK | |

| 9 | Size change ratio after heating(%) | ±0.2 | -0.17 | OK | |