Company Information

Ask for more detail from the seller

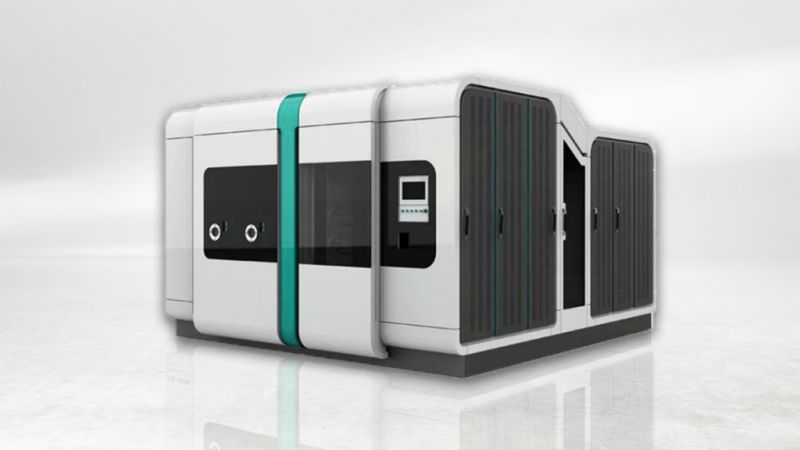

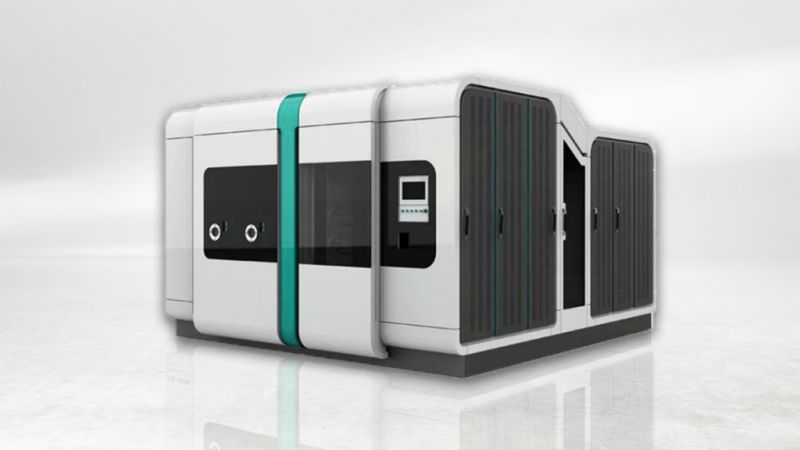

Contact SupplierOur PVD and DLC/PECVD equipment offers a comprehensive solution for various coating technologies within a single machine, specifically designed for industrial applications. This advanced system effectively enhances the durability and performance of cutting and forming tools, precision-engineered components, automotive and aerospace parts, medical devices, and other critical components. By utilizing a magnetron sputtering system, it ensures rapid deposition of functional coatings that significantly boost wear and heat resistance while reducing friction, thereby extending the lifespan of both industrial and consumer products. The equipment achieves dense, smooth coatings comparable to those produced with HIPIMS technology, but does so at an accelerated deposition rate. This flexible solution meets the diverse needs of industries striving for high-quality performance and longevity in their products.

Our system is a compact PVD & PECVD/DLC coating machine designed for easy operation. It offers durable color, functional coatings, and diamond-like carbon coatings.PVD coating equipment flexibilityThe small coating machine is the right-sized PVD and DLC coating system for customers who previously considered thin-film coating systems too complicated or expensive. Differentiate your product by applying the same hard, durable PVD or DLC finishes, which were previously only available to high-volume manufacturing operations, right in your facility.

The compact 6-rack design of this small PVD coating machine can deposit a wide range of durable decorative and functional PVD finishes on metal or plated parts, including some plastics. our system is suitable for both small and higher-volume applications, and many parts per batch means a low cost per part and a fast return on investment.

DLC

Diamond-like carbon coatings.

specifications

System capacity

System footprint

3.4m x 1.6m

Coating area per batch 4.79m2

Number of racks 6

Rack size 100cm x 25.4cm Ø

Coating technologies

Low-temperature cathodic arc vapor deposition

Coating processes

Physical vapor deposition (PVD)

Plasma-enhanced chemical vapor deposition (PECVD) to create diamond-like carbon (DLC) coatings

Available coatings

Pure, alloyed, or reacted zirconium, titanium, chromium, and carbon