Company Information

Ask for more detail from the seller

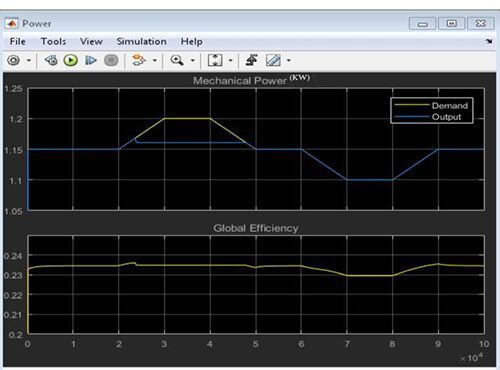

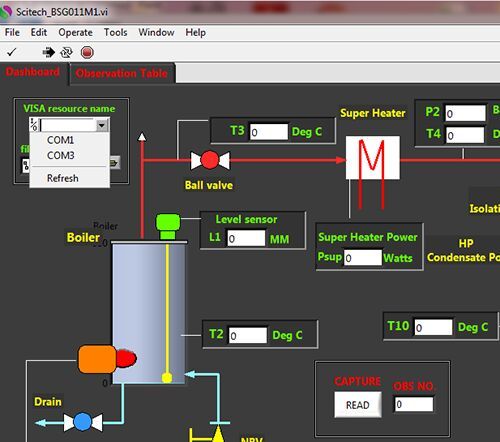

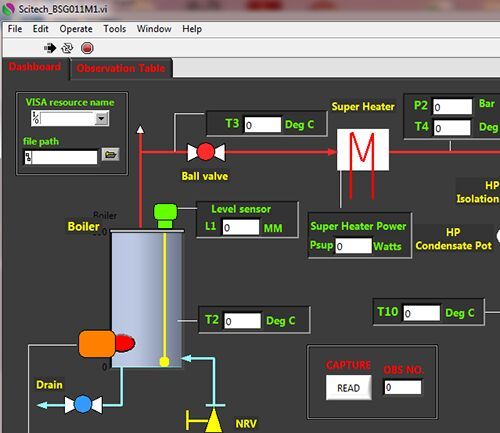

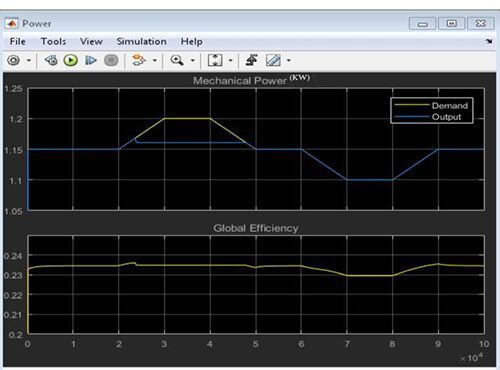

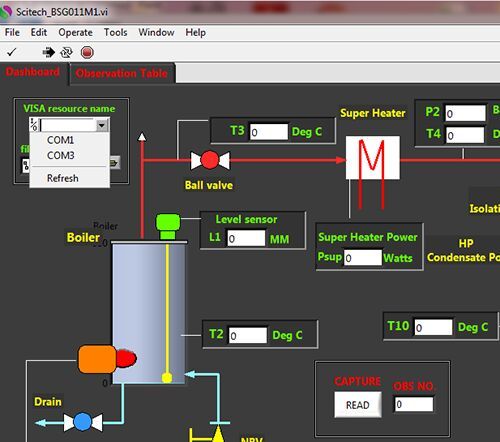

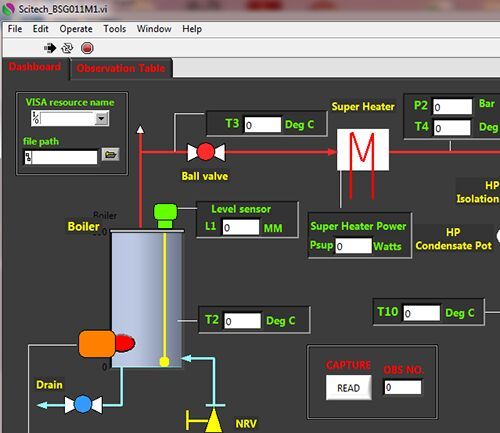

Contact SupplierSci-tech Rankine Cycle Steam Turbine Model BSG 012 is used to drive bulb loads or for heating system. Steam generators and steam engine together form a steam power plant. Steam power plants work according to the Rankine cycle which is still one of the most important industrially used cyclic processes. Steam power plants are mainly used for electrical power generation. The steam generator and the axial steam turbine together form a complete laboratory-scale steam power plant. Sci-tech Rankine Cycle Steam Turbine Model BSG 012trainer serves to familiarize students with the components and principle of operation of a steam generator and enables them to examine the characteristic values of the system. The numerous safety devices of the steam generator can be tested and checked using various monitoring devices. If the steam generator is operated without the steam turbine, the generated steam is directly liquefied in a condenser and fed back into the evaporation circuit via a tank. As all components are clearly arranged on the front panel, the cyclic process can be easily monitored and understood. Sensors record the temperature, pressure and flow rate at all relevant points. The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. Optionally ‘Sci-CalR’ data acquisition software DAQ or SCADA can be included. The steam generator has been constructed according to the Technical Regulations for Steam, pressure-tested and is equipped with all legally required safety devices. Shown below is an example model of a steam turbine system based on the Rankine Cycle. The cycle includes superheating and reheating to prevent condensation at the high-pressure turbine and the low-pressure turbine, respectively. The cycle also has regeneration by passing extracted steam through closed feed-water heaters to warm up the water and improve cycle efficiency. The Saturated Fluid Chamber block models a separate saturated liquid volume and saturated vapor volume and is used to create the boiler and the condenser Specifications 1) Boiler: Independently certified electric boiler with manual control, pressure switches, safe pressure cut out and large capacity relief valve Rated Steam generation @ 100 Degrees C: 100Kg/Hr Steam Pressure: 10Kg/cm sq. Steam Temperature: 184 degrees C Efficiency: @ 85 ~90% Heater: a) Electrical Heaters @ 18KW b) Fuel: Propane consumption @ 5.5Kg Hr Heater or Burner: ON/OFF Electrical Power: 400~440V, 3 Ph, 50Hz OR 200V, 3 Ph, 60Hz Feed Water Pump: 0.38KW Burner Motor: 0.20KW - Boiler Coil (Pressure Parts) (W.P.@10Kg/cm2): Vertical, Coil Type, three pass Design. Fabricated out of SS304 Tubes. Hydraulically tested at 20 Kg/cm2 - Shell Assembly: Insulated with Mineral Wool & cladding with CR sheet. - Base Frame: Fabricated in MS - Economizer: Fabricated from SS304, plates & pipes - Backfire Relief Valve: Reputed make, to release gases at the time of back firing. - Burner assembly: Long lasting - Steam Pressure Gauge: Wika/Baumer make or provision for sensor for digital signalling to computer - Feed Water Pump: Reciprocating Type with surge suppressor. Variable Pulley- With this pulley we adjust the feed water accurately which results in less condensate & good quality of steam. - Mountings & Fittings: Main Steam Stop valve- 20NB- 1 no Auxiliary steam stop valve- 15NB- 1 no Safety valve- 15NB- 1 no Non-return valve on feed water line- 15NB- 1 no Blow down valve-1 no Water Relief Valve (for Feed Water Pump Safety) - 1 no. Parts meeting water / steam will be as follow: Coil- SS304, Water Pump- Brass, Stea