Listing ID #1337957

Company Information

Ask for more detail from the seller

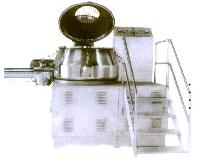

Contact SupplierOur company is engaged in manufacturing and supplying feature packed Rapid Mixer Granulator. Rapid Mixer Granulator, offered by us, is ideal for meeting special needs of tablet manufacturing technology. The Rapid Mixer Granulator reduces processing time and performs more homogeneous mixing. There is uniformity of granule size with Rapid Mixer Granulator. Also, the Rapid Mixer Granulator maintains improved hygiene compliant to cGMP norms.

cGMP : Rapid is designed to achieve all the requirements of cGMP –Curent Good Manufacturing Practices. The components can be easily dismantled, cleaned are very effective to check any leakages and cross contamination due to adherents. The bowl and all the components are of highly polished stainless steel with smooth contours and is crevice less.

The Mixing Bowl :

Granulator :

Bottom Discharge Valve :

Improved Processing :

Electrical :

Automation : To achieve constitancy in the product quality it is desirable to minimize/eliminate the human elements in monitoring the operational parameters of the machine including the end point control. it is also desirable to record/store the critical data which may contribute to product quality. The desired operational data can be saved and hard copy (print out) can also be taken out. To incorporate suitable peovision in the system of data required to be reproduced. As a standard, following parameters are recorded.

R & D : Rapid mixer granulators can be offered in 10Ltrs,R&D or pilot plants. The process parameters derived in the Lab/Pilot scale machines can be scaled up into production machines. These machines can also be offered with PLC’S

Documentation :

General :

Optional :

| Dry mixing | approx. | 3-5 mins. |

|---|---|---|

| Wet mixing | approx | 5-10 mins. |

| Wet Granulation | approx | 5-10 mins. |

| Discharge | approx | 1-1.5 mins |