Company Information

Ask for more detail from the seller

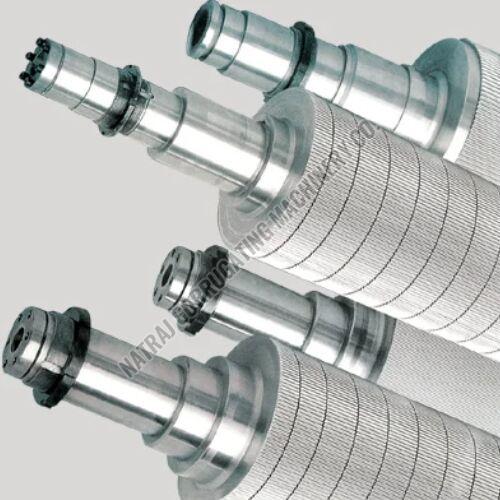

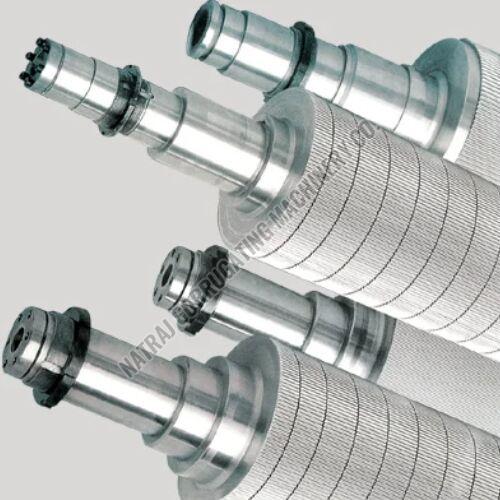

Contact SupplierWe have established ourselves as a trusted and eminent name in the corrugation industry, offering a comprehensive range of roller maintenance services, including corrugation roller regrinding and tungsten carbide coating. Our solutions are performance-driven, focused on enhancing roller life, precision, and operational efficiency.

\r\rKey Features:\r✅ Excellent Performance

Restores worn rollers to near-original specifications, ensuring high-speed and high-quality corrugation output.

✅ Performance-Oriented Design

Every regrinding and coating job is tailored to the exact flute profile and machine compatibility.

✅ Fine Finish

Precision grinding delivers clean, sharp flute profiles for improved bonding and board appearance.

| Material | \r52 MnCr (Alloy Steel) | \r

| Flute Height | \r4.6 – 4.9 mm | \r

| Roller Length | \rUp to 3000 mm | \r

| Coating Option | \rTungsten Carbide (optional) | \r

Enhanced Wear Resistance:

Tungsten carbide coating significantly extends roller life under high-pressure and high-speed operation.

Cost-Effective:

Refurbishing existing rollers with regrinding and coating saves cost over full replacement.

Quick Turnaround:

On-time delivery and responsive service to minimize production downtime.

Corrugated single facers

\rHigh-speed corrugating lines

\rAll flute types (A, B, C, E, etc.)

\r