Company Information

Ask for more detail from the seller

Contact Supplier

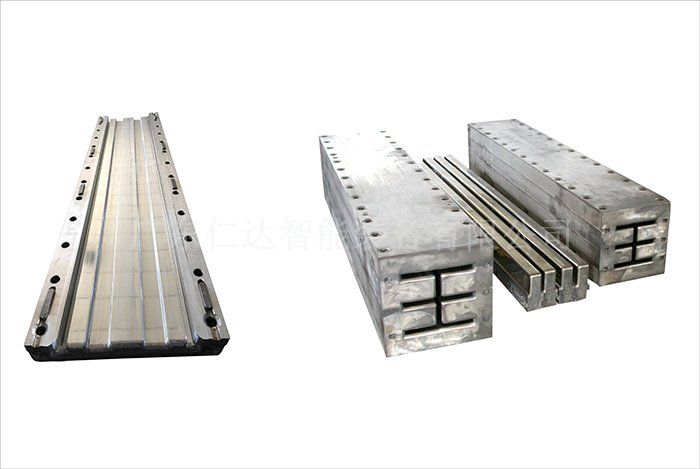

FRP Grating’s Pultruded FRP Gratings are assembled from pultruded shapes. These shapes (I-Bars, T-Bars, etc.) are manufactured by pulling fiberglass rovings and mats through guides, then into a resin bath, then wrapped with a surfacing veil, then finally pulled through a heated die to form the desired bar shape. Once the bars are pulled, they are drilled for crossrods, then assembled by installing the crossrods spaced on 3” or 6” centers (depending on the grating type). These crossrods, that lock the bars into place, are then bonded with epoxy to ensure the bars will not move. Pultruded gratings are typically manufactured with either an Isophthalic Polyester Resin or a Vinyl Ester Resin, but can be manufactured in any resin available.

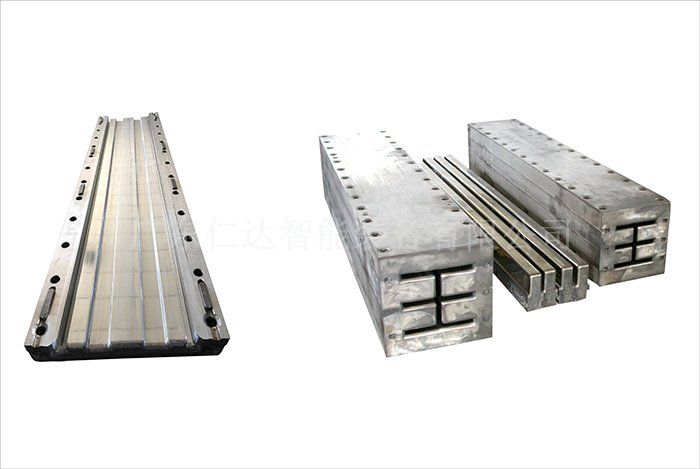

Since Pultruded gratings are manufactured by pulling and assembling load bars and positioning those bars as needed to create panels as required, in addition to our standard panel sizes, we are able to reduce the waste material by manufacturing custom panels to size. We pultrude load bar lengths as required and assemble panels to required widths. There is no need to manufacture a full panel and waste material. In addition, we are able to custom manufacture panels of various sizes and standard styles listed below. Contact us today with any custom requests.

Pultruded Gratings are commonly used in a variety of applications, including, but not limited to:

PULTRUDED FIBERGLASS GRATING:

Corrosion Resistant

Non-Conductive

Low Maintenance

Fire Retardant - ASTM E84, Class 1, F.S. 25 or less

Extended Service Life

Superior Strength in load bar direction

In many cases, fewer supports are required, which can result in a lower cost system

Less wasted material

FRP Grating’s Pultruded FRP Gratings are assembled from pultruded shapes. These shapes (I-Bars, T-Bars, etc.) are manufactured by pulling fiberglass rovings and mats through guides, then into a resin bath, then wrapped with a surfacing veil, then finally pulled through a heated die to form the desired bar shape. Once the bars are pulled, they are drilled for crossrods, then assembled by installing the crossrods spaced on 3” or 6” centers (depending on the grating type). These crossrods, that lock the bars into place, are then bonded with epoxy to ensure the bars will not move. Pultruded gratings are typically manufactured with either an Isophthalic Polyester Resin or a Vinyl Ester Resin, but can be manufactured in any resin available.

Since Pultruded gratings are manufactured by pulling and assembling load bars and positioning those bars as needed to create panels as required, in addition to our standard panel sizes, we are able to reduce the waste material by manufacturing custom panels to size. We pultrude load bar lengths as required and assemble panels to required widths. There is no need to manufacture a full panel and waste material. In addition, we are able to custom manufacture panels of various sizes and standard styles listed below. Contact us today with any custom requests.

Pultruded Gratings are commonly used in a variety of applications, including, but not limited to:

Sunscreens

Benches

Platforms

Bridges

Walkways

Trench Covers

Manhole Covers