Company Information

Ask for more detail from the seller

Contact SupplierReverse Engineering Solutions in Bangalore at Quality Laboratory

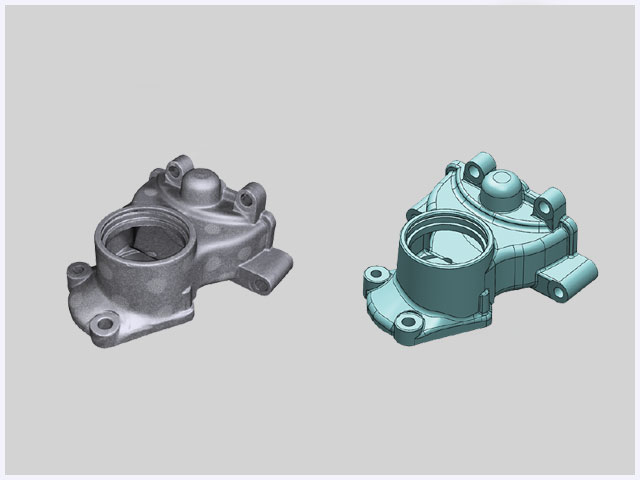

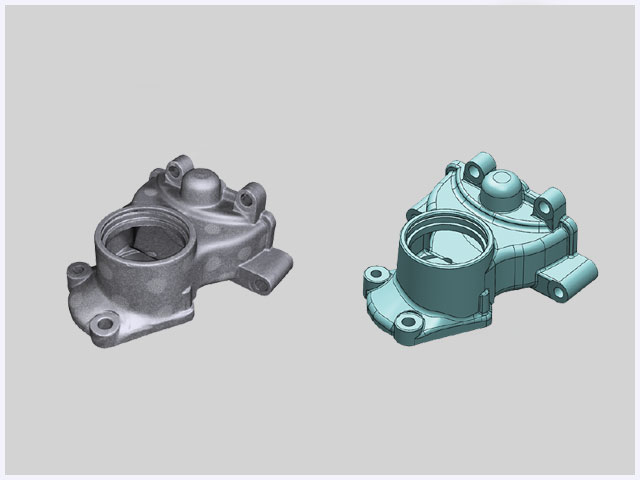

Have a finished product but no design files? Reverse engineering is the ideal solution to recreate STL data and CAD models, enabling accurate inspection and seamless manufacturing.

Reverse engineering, also called "backward engineering," involves analyzing an existing object to understand its design, function, or production process. By utilizing advanced tools and techniques, reverse engineering reconstructs digital models of a product with minimal information about its original design.

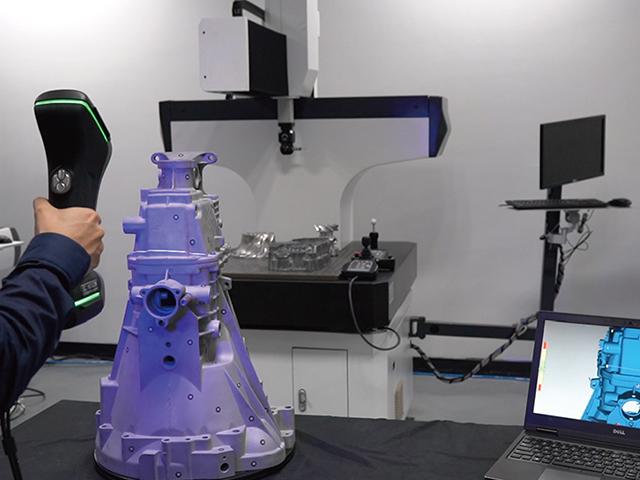

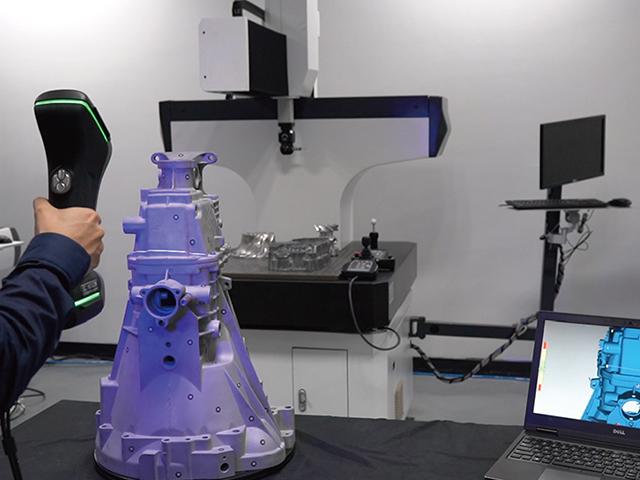

At Quality Laboratory, we specialize in reverse engineering using advanced technologies to deliver highly precise results. Our process includes:

We offer expertise in reverse engineering gears (spur and helical), prismatic profiles, and freeform surfaces, ensuring reliable and tailored solutions for various industries.

KSCAN – MAGIC COMPOSITE 3D SCANNEROur KSCAN – MAGIC COMPOSITE 3D SCANNER enhances reverse engineering efficiency and accuracy. Equipped with cutting-edge infrared laser + blue laser technology and a built-in photogrammetry system, it captures ultra-high details across five working modes. Its flexibility allows scanning parts ranging from a few centimeters to several meters, making it suitable for various applications, including:

Whether you’re recreating a lost design, optimizing an existing product, or inspecting components for manufacturing, Quality Laboratory provides precise and reliable reverse engineering services.

Partner with us for tailored solutions that meet your needs. Contact Quality Laboratory today to learn more!