Listing ID #1474949

Company Information

Ask for more detail from the seller

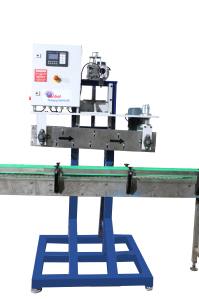

Contact SupplierRinsing Filling and Capping Machine For Mineral Water

Technical Specification : Bottles are conveyed through air from the feeding end. The feeding end conveying is neck holding type. The bottles are picked up from the conveyor end and are inverted for washing, after washing bottles are transferred to the filling rotor where the filling is done. Filling is time based. After filling the bottles pick up the cap and go towards the capping head where the head descends on the cap of the bottle and tighten it. Caps in the bowl are oriented and brought out through the chute. The container is then released on to the out feed conveyor of the machine. Then it conveyed to shrink tunnel mounted on conveyor.

Rinsing Counter Pressure Filling and Capping Machine For Areated Water

Technical Specification : Bottles are conveyed through air from the feeding end. The feeding end conveying is neck holding type. The bottles are picked up from the conveyor end and are inverted for washing, after washing bottles are transferred to the filling rotor where the filling is done. Filling is time based. After filling the bottles pick up the cap and go towards the capping head where the head descends on the cap of the bottle and tighten it. Caps in the bowl are oriented and brought out through the chute. The container is then released on to the out feed conveyor of the machine.