Listing ID #3878901

Company Information

Ask for more detail from the seller

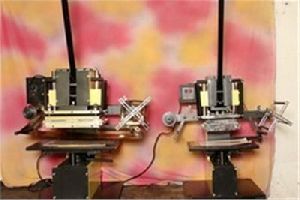

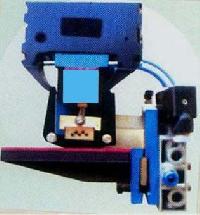

Contact SupplierThe foil transfer on the textile is done by the means of stamping process.

The foil stamping process takes place in various stages. In the first stage the adhesive is transferred to the textile through the Flat Bed screen or a Rotary Screen. The adhesive coated textile passes through the Foil Stamping Machine where in there is an unwinding device for textile and foil roll. These simultaneously pass through a hot stamping device after which, the foil is transferred to the Precoated textile.

In the next stage, the textile goes through the winding section where the foil and the textile are separated and individually wound.

Roll to roll foil stamping can be done in various shades and colours like gold, silver, multicolor and tone to tone. This stamping can be done in very minute and small designs also with a raised effect, if the stamping order is in large quantities. This type of foil stamping is very useful if followed through on a finished dyed or printed textile and if any additional effects are required.

This type of roll to roll foil stamping machine is used in garments where particular portions of the textiles like sarees, dress materials, furnishings etc. need to be highlighted by the foil.

| Working width | Mechanical Speed | Electrical Power | Compressed Air | Space Requirement | Roll |

|---|---|---|---|---|---|

| 1200 mm | 40 m / min | 9 kW | 6 - 8 bar | 5 m Length x 4.5 m Width | Hard chrome plated |

| 1600 mm | 40 m / min | 12 kW | 6 - 8 bar | 5 m Length x 5 m Width | Hard chrome plated |

| 1800 mm | 40 m / min | 15 kW | 6 - 8 bar | 5 m Length x 5.5 m Width | Hard chrome plated |

| Working width | Mechanical Speed | Electrical Power | Compressed Air | Space Requirement | Roll |

|---|---|---|---|---|---|

| 1200 mm | 40 m / min | 9 kW | 6 - 8 bar | 5 m Length x 4.5 m Width | Hard chrome plated with oil jacketed drum |

| 1600 mm | 40 m / min | 12 kW | 6 - 8 bar | 5 m Length x 5 m Width | Hard chrome plated with oil jacketed drum |

| 1800 mm | 40 m / min | 15 kW | 6 - 8 bar | 5 m Length x 5.5 m Width | Hard chrome plated with oil jacketed drum |