Company Information

Ask for more detail from the seller

Contact SupplierRoof Sheet Making Machine Roll Forming Machine

DESCRIPTION

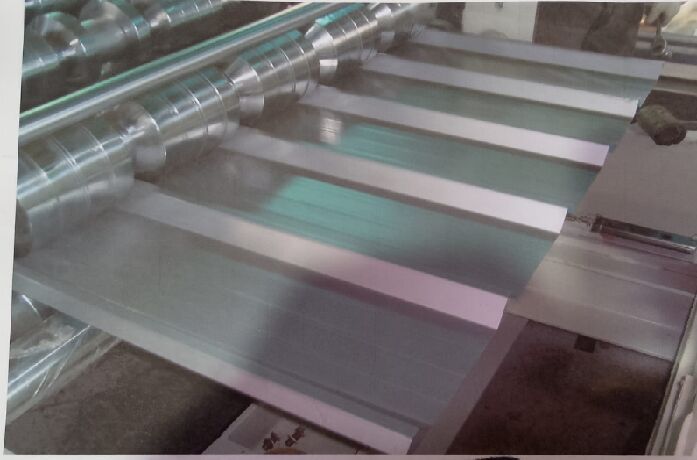

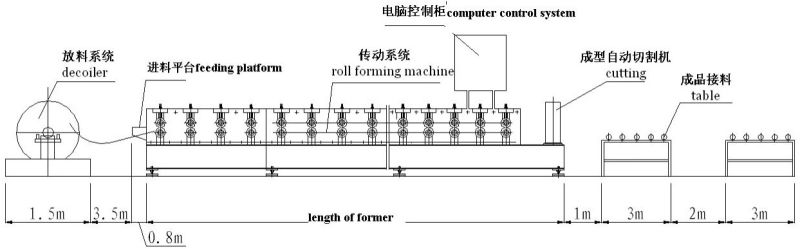

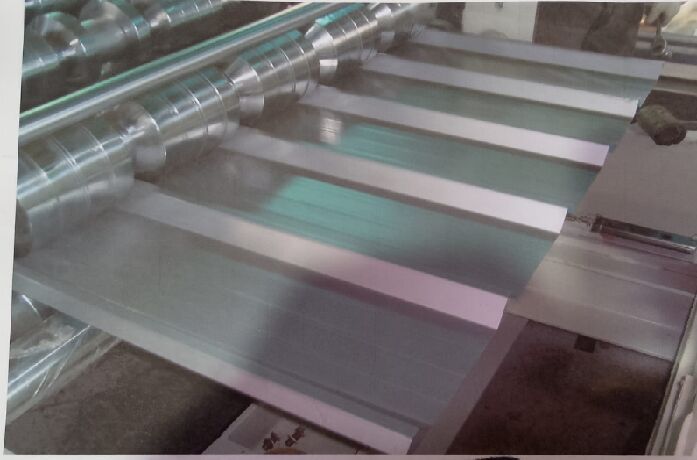

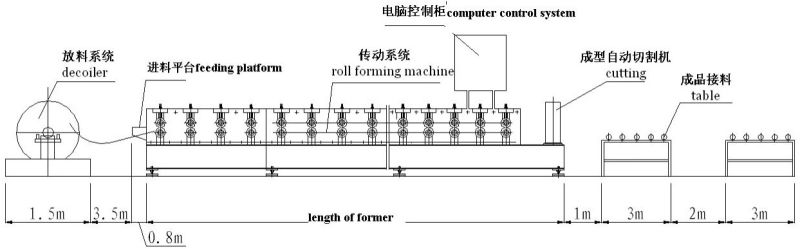

The Automatic Roof Sheet Making Machine Roll Forming Machine is designed to automatically produce roofing sheets. These sheets are commonly used in construction for roofing purposes due to their durability and weather resistance. The machine uses a roll forming process to shape and cut the sheets to the desired specifications.

Introduction

Automation: The machine is fully automatic, which means it can operate without constant human intervention. This increases production efficiency and reduces labor costs.

Precision: The roll forming process ensures high precision in the shape and size of the roofing sheets. This consistency is crucial for ensuring the quality of the final product.

Versatility: The machine can be customized to produce different types and sizes of roofing sheets, making it versatile for various construction projects.

Durability: The machine is built with high-quality materials to ensure long-term durability and reliability.

Working Principle

The working principle of the Automatic Roof Sheet Making Machine Roll Forming Machine involves feeding a flat sheet of metal into the machine, which then passes through a series of rolls. These rolls gradually shape the metal into the desired profile. The machine also includes cutting mechanisms to trim the sheets to the required length.

Specification

item | value |

Rolling thickness | 0.3-0.8mm |

Feeding width | 1250mm |

Voltage | 380V, 50Hz, 3 phrases; or as customer needing |

Product name | Roll forming machine |

Roller material | 45#steel Chrome Plated |

Cutting blade material | Cr 12 High Grade Steel |

Control system | PLC+touch Screen |