Listing ID #4922166

Company Information

Ask for more detail from the seller

Contact SupplierRotary Drum Dryer also known as a rotary kiln, is employed to reduce or minimize the moisture content of agro and forest waste, it is done by bringing it into direct contact with heated gas. The rotary dryer is made up of a large, rotating cylindrical tube. The dryer discharge end is lower than the material feed to convey the material through the dryer under gravity.

Rotary Drum Dryer is suitable to dry raw material which contains high moisture up to 50% and more. JK make CE Certified Rotary Drum Dryer is special designed to reduce or minimize the moisture content of agro and forest waste to 10% or less for briquetting, JK Rotary drum dryer combines the function of drying and cooling, thus save 30-50% energy.

Rotary dryers are known as the replacement of industrial dryers. They are able to process a wide variety of materials, and can lend a hand in nearly any industry requiring industrial drying solutions. Some of the most common industries and materials in which rotary dryers are employed include are typical material rotary dryers process include agricultural by products & Waste, animal feeds, animal waste, Forest Waste, Paddy Husk, coconut Shell, bio solids, concentrates, municipal sludge & municipal waste.

| MODEL NO. | PRODUCTION | POWER REQUIRED |

|

JKRTD |

3000 kg/h |

CUSTOMIS |

|

JKRTD |

8000 kg/h |

CUSTOMIS |

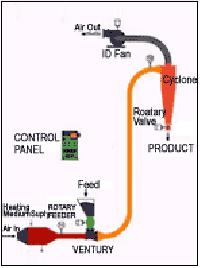

Hot air is generated by wood/ Briquettes. Material is conveyed by screw at feeding point. Material is spreaded by lifters in horizontal shell. Hot air is sucked by fan through shell in the presence of wet material. With the rotation of cylinder, the material flow down to the lower end with the effect of gravity and discharge after drying, at end point material comes out with the help of cyclone & Rotary valve with required moisture. Evaporated moisture goes in atmosphere by sucking fan.

Various models of Rotary Dryer are available basis on Moisture content and production requirements. Complete System of Rotary Dryer is automated where moisture content is adjustable.

After the damp raw material is put into the dryer from one end, it is turned over through string-up rake inside the cylinder and distributed uniform in the dryer and contacted with counter current hot air fully.

It speeds up heat and mass conducting of dry. During the period of dry raw material is effected by stirring-up rake with gradient and hot air. It can be moved and passed through the dry region and to star valve and then discharge the finished product.

During the Drying Process, the best moisture content to pellet and briquette is about 13-15% and 11-12%, the function of the Rotary Dryer is to make the crushed pieces with suitable moisture.

Our rotary dryers are built to the highest quality standards, with longevity in mind. The best part about buying a Jay Khodiyar rotary dryer is that you get the security of knowing your equipment is backed by over 60 years of experience, material and process knowledge, and a proven track record.

We’ve built a reputation on building the best rotary dryers in the industry. All of our dryers are custom designed to suit the unique processing needs of your material. Whether you require low or high inlet temperatures, short or long residence times,counter-current or co-current flow, JAY KHODIYAR’s design team can design a rotary drum dryer for your application.