Listing ID #3866294

Company Information

Ask for more detail from the seller

Contact SupplierApplication:

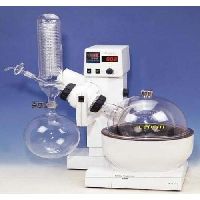

Batch or Continuous Operations under vacuum or atmospheric pressure.

"Evaporation of solvents containing heat sensitive materials or solids under reduced pressure. Vacuum drying of wet solids. Especially designed for high boiling solvents. Degassing of liquids.

Principal of Rotary Evaporator

The system consists of:

1.Thin Film Evaporation.

2.Large Surface Area

2.Uniform transfer of heat through its glass wall to the thin film.

A wide range of evaporation flask volumes from 1 liter up to 50 liter allows finding an appropriate size of distillation performance from the Lab up to the Production Plant.

Its broad temperature range from +20¡Æ C to +180¡Æ C opens up a wide range of applications and it's modular design makes it possible to fully adapt the evaporator to your individual needs.

Outstanding Features

1.High performance sealing system.

2.Dual over-temperature cutout devices

3.Manually adjustable maximum temperature control

4.Protection hood for the oil/water bath & rotating flask

5.All components are designed to suit high Vacuum

6.High efficiency with limited space requirements

7.High Distillation rates/Solvent Recover

8.Low Operating Temperature

9.High purity of distillate/Solvent

10.All evaporators can be upgraded for future needs

Overview of the System

A typical set up of Rotary Evaporator glassware consists of an evaporating flask, a receiving flask & a condenser. The evaporating flask holds the sample to be evaporated. Once a sample is placed in the evaporating flask, it is lowered in to a heated water bath and is rotated in the water bath. The rotation of the evaporation flask creates a thin film of sample on the inside of the glassware. Increase surface area encourages evaporation of the molecules. Heated water encourages the free flow of molecules to move toward the condenser to be collected in the receiving flask. The receiving flask collects the condensate that comes from the condenser for evaluation of the pure solvent or proper waste disposal

1.The system consists of:

2.Evaporating Rotating Flask - 1 no..

3.Induction Electric gear motor -1 no.

4.Cooling Condenser - 1 no.

5.Receiver Flask - 2 nos.

6.Instrument panel includes

7.RPM Controller

8.Bath Temperature Controller

9.Stand

| Model | Rotating FlaskCapacity (ltrs.) | Rotating Speed (rpm) | Electric MotorRating | Condenser CoolingArea | Receiver FlaskCapacity (liters.) | Power Supply(Volt/Hz) | Bath Rating |

| SRFE2 | 2 | 0-80 | 40 Watt | 0.15 | 1 | 230 V, 50 Hz | 2 |

| SRFE3 | 3 | 0-80 | 40 Watt | 0.15 | 1 | 230 V, 50 Hz | 2 |

| SRFE5 | 5 | 0-80 | 40 Watt | 0.15 | 2 | 230 V, 50 Hz | 2 |

| SRFE10 | 10 | 0-80 | 0.25 HP | 0.20 | 5 | 230 V, 50 Hz | 4 |

| SRFE20 | 20 | 0-80 | 0.25 HP | 0.30 | 10 | 230 V, 50 Hz | 4 |

| SRFE50 | 50 | 0-80 | 0.25 HP | 0.50 | 20 | 230 V, 50 Hz | 6 |