Company Information

Ask for more detail from the seller

Contact SupplierBacked with rich industry experience, we are offering Rotary Sand Mixer based on the advanced technology. Customers can avail from us Rotary Sand Mixer with high efficient, reliable, durable and economic features. Our Rotary Sand Mixer has a compact and rugged construction that is easy to maintain. The Rotary Sand Mixer, offered by us, consists of drive mechanism, chassis, DOUBLE 'S' SHAPED BLADE ASLY, mixer rotor, dust collector, automatic quantitative water device, weighing hopper, additional material weighing device, automatic electrical control system and some other components.

HSHS Series High Speed Rotary Sand Mixer :

HS Series sand Mixer is one kind of self-developed equipment based on the advanced technology in the digestion and absorption from European counterparts for sand mixture with high efficient, reliable, durable and economic features. The entire construction is compact, rugged and easy to maintenance.

Sand Mixer Components :

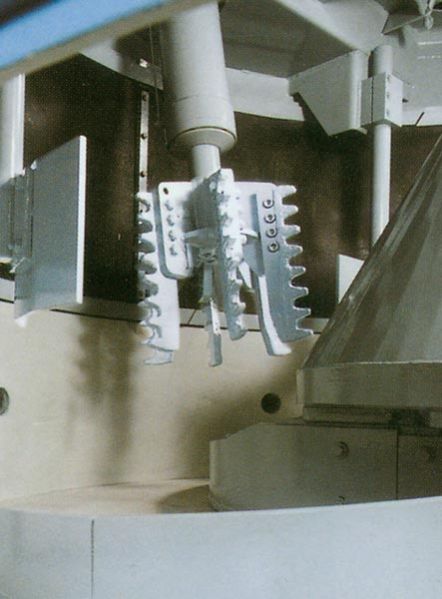

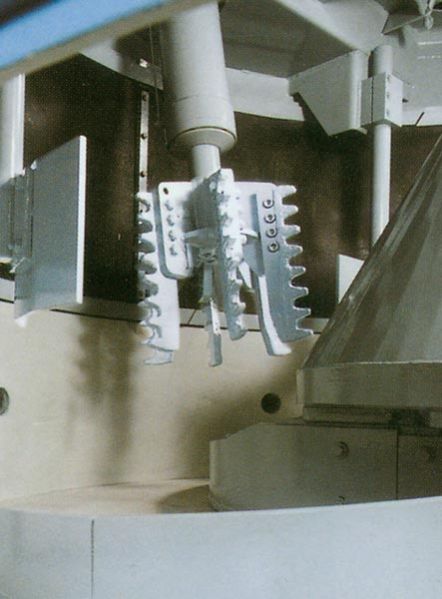

HS Series High Speed Rotary sand Mixer consists of the following components: drive mechanism, chassis, DOUBLE 'S' SHAPED BLADE ASLY, mixer rotor, dust collector, automatic quantitative water device, weighing hopper, additional material weighing device, automatic electrical control system and some other composition.

Sand Mixing Principle And Characteristics :

Raw materials is intermittently batch fed into the sand mixer through their respective weighing devices. The mixing stirrer is continuously rotating during feeding. The large double-S shape stirrer and the high speed rotor extending from the top down rotate in a reverse direction, while the mixer chassis and the guide plate remained motionless. This dynamic and static motion combination ensures that the sand will be quickly and strongly mixed and reach a high degree of uniformity. All of the particles among the mixture will move up and down as well as in vertical and horizontal direction and constantly be mixed and loosened.

SEW drive mechanism, higher reliability, large production, energy efficiency is high, especially economic , The molding sand quality is stable, uniform and loose. V-belt drive, variable frequency to adjust speed, soft start to protect the motor. Sand is discharged from the side rapidly without impurity. minimal maintenance requirements, automatic lubrication device, easy to replace worn parts. machined mixer chassis and cylinder ring ,stirrer ,chassis and the cylinder wall assembled with high precision, so wear and tear is minimum.

Quantitative And Weighing Systems :

Design accuracy and a wide range of adaptability. Even in harsh working environments to ensure the desired composition of sand and water by molding sand. Feeding, molding sand mixture, with the various components such as sand, new sand, bentonite and coal, etc., is fed into the sand mixer through the same exit at the same time after weighing to achieve pre-mixed effect. this can often omit to immediately add water during premixing process. Water is injected directly into the mixture through the radial direction in order to avoid the formation of the sand group. Molding sand achieve a high degree of mixing effect in a short period through this technology.

New sand and additional material can be fed into the sand mixer from the top down or also from the side through the blowing device to join. This can reduce the ash loss and improve the mixing efficiency. the biggest advantage of blowing feeding is that: it has wide adaptability, the position of new sand and additional material weighing device can be chosen arbitrarily, the sand plant arrangement is more flexible and. Convenient.