Company Information

Ask for more detail from the seller

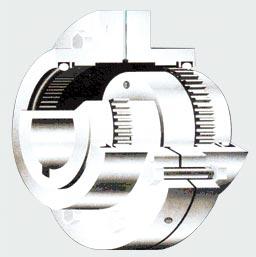

Contact SupplierCommitted to quality, we bring forth precision engineered Roto Gear Couplings. These Roto Gear Couplings are well suited for any conceivable mechanical power transmission systems in all industries. The teeth profile of Roto Gear Couplings provides good mechanical flexibility and compensation of parallel, angular and axial misalignment of the connected shafts.

Roto Gear Couplings are available in following executions :

| Coupling | Max. Speed | Bore(MM) | Approx | GD2 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | HP/100RPM | MaxTorqueKgM | (RPM) | Pilot | Max | WT(kg) | KG. M 2 | A | B | C | E | G | L | L1 | L2 | L3 |

| RG 01 | 15 | 107 | 6350 | 15 | 50 | 11 | 0.14 | 172 | 110 | 65 | 18 | 5 | 60 | 56 | 117 | 50 |

| RG 02 | 34 | 243 | 5100 | 20 | 60 | 16 | 0.21 | 186 | 125 | 85 | 18 | 5 | 85 | 66 | 137 | 62 |

| RG03 | 63 | 451 | 4050 | 30 | 75 | 27 | 0.48 | 222 | 150 | 105 | 21 | 5 | 110 | 87 | 179 | 80 |

| RG 04 | 120 | 859 | 3300 | 35 | 90 | 41 | 0.94 | 251 | 175 | 130 | 21 | 5 | 130 | 106 | 217 | 97 |

| RG05 | 182 | 1303 | 2850 | 40 | 110 | 62 | 1.9 | 292 | 200 | 155 | 26 | 10 | 140 | 112 | 234 | 106 |

| RG06 | 279 | 1998 | 2575 | 45 | 125 | 86 | 3.06 | 318 | 230 | 175 | 26 | 10 | 160 | 126 | 262 | 118 |

| RG07 | 484 | 3465 | 2160 | 50 | 140 | 122 | 5.25 | 352 | 260 | 205 | 26 | 10 | 180 | 142 | 294 | 135 |

| RG08 | 628 | 4496 | 1980 | 60 | 160 | 181 | 8.52 | 382 | 290 | 230 | 26 | 10 | 192 | 156 | 322 | 147 |

| RG09 | 786 | 5628 | 1725 | 70 | 180 | 212 | 15.05 | 433 | 330 | 250 | 26 | 10 | 210 | 166 | 342 | 157 |

| RG10 | 1150 | 8234 | 1450 | 100 | 220 | 292 | 30.51 | 492 | 390 | 310 | 26 | 10 | 220 | 182 | 374 | 172 |

| RG11 | 1540 | 11026 | 1250 | 110 | 260 | 553 | 56.83 | 546 | 445 | 350 | 30 | 10 | 250 | 202 | 414 | 190 |

| RG12 | 2052 | 14692 | 1130 | 120 | 300 | 712 | 88.6 | 592 | 490 | 400 | 30 | 10 | 290 | 241 | 492 | 227 |

| RG13 | 2793 | 19998 | 980 | 140 | 330 | 982 | 138.8 | 681 | 555 | 440 | 35 | 10 | 320 | 263 | 536 | 240 |

| RG14 | 3992 | 28583 | 890 | 200 | 370 | 1323 | 291.31 | 732 | 610 | 500 | 35 | 10 | 340 | 280 | 570 | 262 |

| RG15 | 4854 | 34754 | 800 | 250 | 410 | 1703 | 353.11 | 782 | 660 | 540 | 35 | 15 | 385 | 321 | 657 | 302 |

| RG16 | 8380 | 60000 | 730 | 275 | 455 | 2551 | 690.71 | 902 | 755 | 625 | 45 | 20 | 425 | 352 | 724 | 333 |

| RG17 | 11916 | 85318 | 640 | 325 | 520 | 3622 | 1235.31 | 1003 | 855 | 720 | 45 | 20 | 490 | 403 | 826 | 385 |

| RG18 | 15781 | 112992 | 580 | 350 | 610 | 4862 | 1965.71 | 1102 | 950 | 810 | 55 | 20 | 535 | 452 | 924 | 428 |

| RG19 | 20804 | 148956 | 510 | 400 | 710 | 6383 | 3012.31 | 1252 | 1050 | 910 | 55 | 30 | 560 | 486 | 1002 | 456 |