Company Information

Ask for more detail from the seller

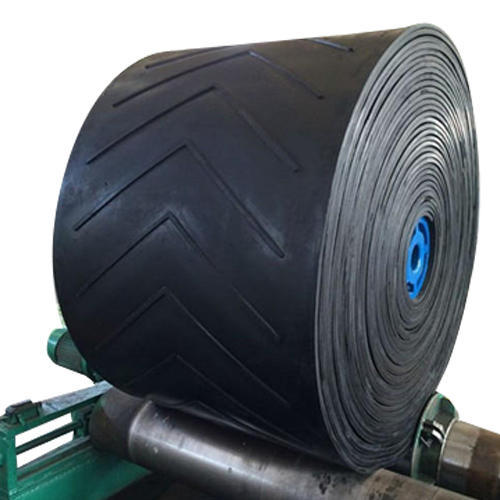

Contact SupplierSandhya Enterprises supplier of Rubber Conveyor Belts. size:

1.6mm Thickness 2Ply to 3ply

2.8.0mm Thickness 2ply to 3ply

3.10.mm Thickness 3 to 4ply

4.12.0mm Thickness 3 to 4ply

Width 100mm to 1500mm.

Use for RMC Plant , Cement Plant and Crusher Plant.Conveyor belts are mechanical devices used to transport materials or objects from one point to another in a continuous manner. They are widely used in various industries, including manufacturing, mining, agriculture, logistics, and more. Conveyor belts consist of a continuous loop of flexible material that is driven by pulleys or rollers, allowing for efficient movement of goods or materials.

Here are some key features and components of conveyor belts:

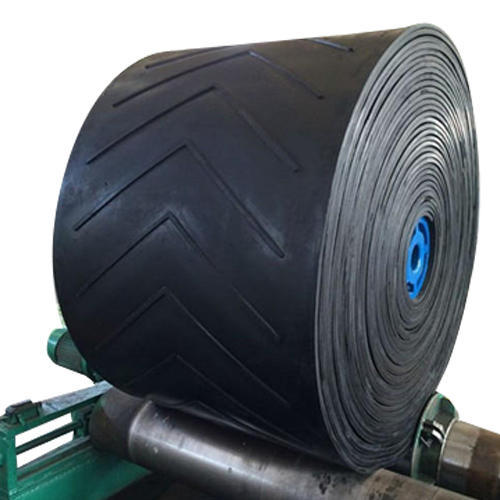

1. Belt material: Conveyor belts are typically made from various materials depending on the specific application requirements. Common belt materials include rubber, PVC (polyvinyl chloride), polyester, nylon, metal, or a combination of these materials. The choice of material depends on factors such as the type of material being conveyed, its weight, abrasion resistance, temperature resistance, and environmental conditions.

2. Belt structure: Conveyor belts are constructed with layers of material that provide strength, flexibility, and durability. The most common belt structure consists of a carcass, which is the core layer that provides tensile strength, and one or more cover layers that protect the carcass from wear, abrasion, and external elements.

3. Drive system: Conveyor belts are driven by a motorized pulley, drum, or a set of rollers. The drive system applies power to the belt, causing it to move. The drive can be located at either end of the conveyor or at intermediate points, depending on the length and configuration of the conveyor system.

4. Rollers and idlers: Conveyor belts run on rollers or idlers, which support and guide the belt along the conveyor path. These rollers can be made of steel, rubber, or other materials, and are designed to minimize friction and facilitate smooth movement of the belt.

5. Belt tracking system: To ensure proper alignment and tracking of the belt, conveyor systems may include a tracking mechanism. This can be in the form of adjustable idlers or automated systems that help keep the belt centered and aligned on the conveyor.

6. Accessories: Various accessories can be added to conveyor belts to enhance their functionality and safety. These may include belt cleaners to remove debris and material buildup, belt fasteners for joining belt ends, skirt boards to contain material on the belt, and safety devices such as emergency stop switches and belt misalignment sensors.

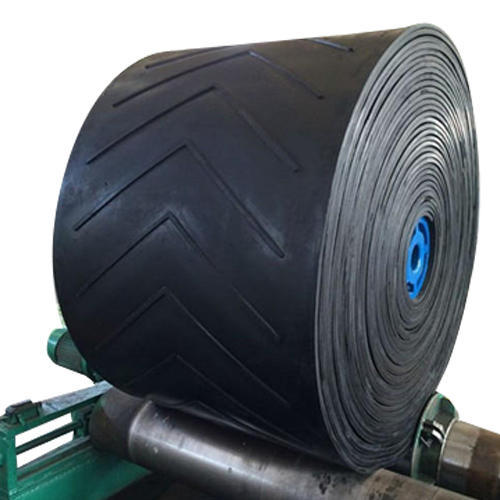

7. Specialized belts: There are specialized conveyor belts designed for specific applications, such as heat-resistant belts for high-temperature environments, food-grade belts for the food industry, oil-resistant belts for the mining industry, and more. These belts are formulated with specific materials and features to meet the unique requirements of their respective industries.

Proper maintenance and regular inspection of conveyor belts are crucial to ensure their efficient and safe operation. This includes monitoring belt tension, checking for wear or damage, and performing routine cleaning and lubrication.

When selecting a conveyor belt, it is important to consider factors such as the type and weight of the material being conveyed, the operating conditions (including temperature, humidity, and presence of chemicals), the required speed and capacity, and any specific industry regulations or standards.

Consulting with experienced conveyor belt suppliers or manufacturers can help in choosing the appropriate belt type and configuration for your specific application needs.