Company Information

Ask for more detail from the seller

Contact SupplierMaterial: Gaskets can be made from various materials, including rubber, cork, paper, metal, silicone, and fiber materials like asbestos (though asbestos is no longer used due to health concerns). The choice of material depends on factors such as the application, operating conditions (temperature, pressure, and chemical compatibility), and the specific sealing requirements.

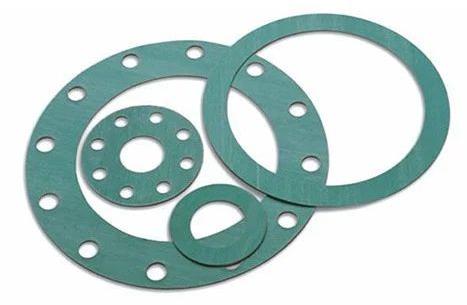

Shape and Size: Gaskets come in different shapes and sizes to match the mating surfaces they seal. They can be circular, oval, rectangular, or have a custom shape based on the application. Gasket size is typically specified by inner diameter (ID), outer diameter (OD), and thickness.

Compression: Gaskets are designed to be compressed between the mating surfaces to create a reliable seal. The compression can be achieved by tightening bolts or fasteners that apply pressure, ensuring the gasket fills any irregularities and forms a tight seal.

Types: There are various types of gaskets, including flat gaskets, spiral wound gaskets, ring gaskets, and O-ring gaskets. Each type has its specific design and application suitability.

Temperature and Pressure Rating: Gaskets have temperature and pressure ratings that indicate their ability to withstand different operating conditions. These ratings are crucial to selecting the appropriate gasket material and design for the specific application.

Chemical Compatibility: Gasket materials should be selected based on their compatibility with the fluids or gases they will come into contact with. Different materials have varying resistance to specific chemicals, oils, fuels, and other substances.