Company Information

Ask for more detail from the seller

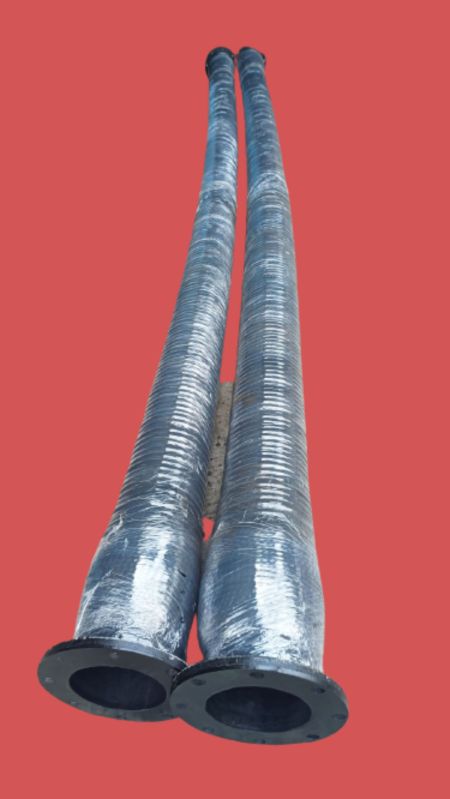

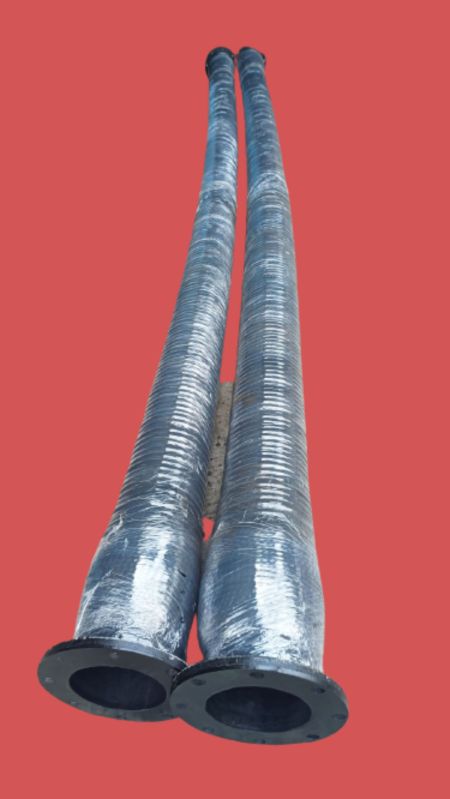

Contact SupplierHere are the packaging details for Rubber Hoses, commonly used in a variety of applications, including construction, mining, industrial machinery, and fluid transport systems. Packaging Details: Rubber Hoses Product Overview: Product Name: Rubber Hoses Material: Typically made of rubber compounds such as natural rubber, synthetic rubber (e.g., NBR (Nitrile Butadiene Rubber), EPDM (Ethylene Propylene Diene Monomer), SBR (Styrene Butadiene Rubber)), and often reinforced with textile fibers or steel wire to increase strength and flexibility. Applications: Rubber hoses are used in fluid transport (water, oil, slurry, chemicals, etc.), mining, automotive, construction machinery, agriculture, and industrial equipment. Sizes and Lengths: Available in a wide range of diameters (from 1/4\\\" to 12\\\") and lengths (from 1 meter to 50 meters or more), depending on the specific application. Packaging Configuration: 1. Coiled Packaging (For Standard Hoses): Coil Form: The most common packaging method for rubber hoses, where the hose is coiled in a circular shape for easier handling and storage. Coil Diameter: The coil diameter typically ranges from 300 mm to 800 mm depending on the size and rigidity of the hose. Coil Length: Coils are usually made to a length of 10 meters to 50 meters per coil, though custom lengths are also available depending on the order. Securing the Coil: The hose is tightly coiled to prevent tangling, often secured with plastic bands, nylon straps, or metal wire. Shrink-wrapping or plastic wrapping is used to protect the hose from dirt, moisture, and external damage. Some hoses are also wrapped with PVC tape or plastic film for additional protection. 2. Reel Packaging (For Longer or Heavier Hoses): Reels: For longer lengths of hose, larger diameter hoses, or heavier-duty hoses, packaging in reels is common. Reel Materials: Reels can be made from wood, plastic, or metal depending on the application and required durability. Reel Size: Reel diameter can range from 800 mm to 2000 mm, depending on the size of the hose being wound. Reel Packaging: The hose is wound around the reel in layers and secured to prevent uncoiling. Reels are often shrink-wrapped or plastic-wrapped to protect the hose from environmental factors during transportation. Labeling and barcode stickers are often applied directly to the reels for easy identification. 3. Bulk Packaging (For Large Orders or Custom Orders): Bulk Packaging: For large orders or bulk shipments, rubber hoses may be bundled together and shipped on pallets or in crates. Bundling: The hoses are bundled and tied securely, often with nylon bands or ropes to maintain their shape and prevent movement during transport. Palletized Packaging: Multiple bundles of hoses are stacked on wooden or plastic pallets for easier handling and shipping. The bundles are often shrink-wrapped to protect them from dirt, moisture, and dust. Crate Packaging: In some cases, especially for export, rubber hoses may be placed in wooden crates for added protection during transit. Crates are typically sealed to ensure the safety of the hoses from external elements. 4. Boxed Packaging (For Smaller Quantities or Custom-Length Hoses): Corrugated Boxes: For smaller orders or custom-length hoses, individual hoses may be cut to size and packed in strong corrugated cardboard boxes. Box Dimensions: The size of the box will depend on the hose\\\'s diameter and length, but it typically ranges from 50 cm to 100 cm in length and 30 cm to 50 cm in width. Protection: Inside the boxes, the hoses may be wrapped in plastic film or bubble wrap to prevent damage. Foam or paper inserts may be used to prevent the hose from moving within the box. Shipping Considerations: Moisture Protection: Since rubber hoses can degrade when exposed to moisture, it’s important to protect them with shrink wrap or plastic covering during shipping to prevent water damage.