Company Information

Ask for more detail from the seller

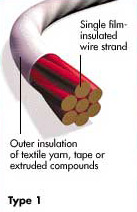

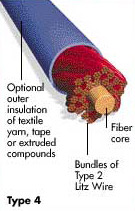

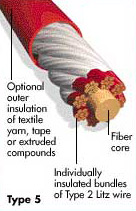

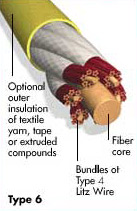

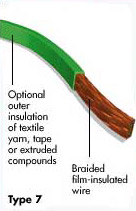

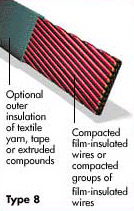

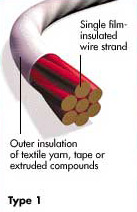

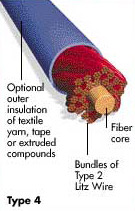

Contact Supplier<p>Litz wire conductors are beneficial for reducing AC losses in high frequency windings. Parashar Vidyut udyog offers litz wire in many constructions with multiple layers of insulations to meet meet voltage withstand requirements. Litz wire is a bunch of several strands of enamelled copper wire. It’s construction vary from a simple bunch of conductor or multiple cores laid up together. </p> <p> </p> <p>The Litz wire is designed to reduce the skin effect and proximity effect losses in conductor at high frequencies up to 1 MHz. Litz wires are typically used in HF transformers, HF inductors, electronic chokes, Toroidal coils, proximity switch, relays, Induction heating, induction, motors, sonar equipment, Inverters, power supply units, SMPS, ultrasonic generators, medical , sterlization equipment, AC-DC converters, Identification systems, magnetic loading, Hearing aids, repeating coils, deflexion yokes, fluorescent lamp ballast, solar inverters, wind power generators, UPS, Eximer Laser and in many other high frequency applications.</p> <p> </p> <p>Litz Wire sizes are generally expressed in abbreviated format i.e. N/XX, Where N equals the number of strands, and XX is the conductor diameter of each strands in SWG/AWG/mm. For example, a typical size of a Litz wire would be expressed as "90/46 SWG" or 90 strands of 46 SWG (0.061 mm).</p> <p> </p> <p>We have a range of Litz Wire and are manufactured from enamelled copper wires made up of high quality copper rods and modified polyurethane, polyesterimide wire enamels as basecoat and aromatie / polyamide as top coat. These are suitable for thermal class 155°C to 240°C. These wires have very good self-fluxing, solderability and high thermal properties.</p> <p> </p> <p>Litz wire are avialable in two forms Served or Unserved. Serving means that the bunched enamelled copper wire have a outer protective covering of one or two lapping of silk yarn, nylon, polyester, Cotton or Nomex (High temperature aramid). Typically serving is used to protect thin film insulation of the individual strands. The serving adds about 0.06 mm to the diameter of Litz Wire. The first lapping of serving is applied to the bunched wires in a direction opposite to the twist of the bunched wires. If a second lapping is to be applied it shall be in the opposite direction to the first lapping. The covering is uniform in quality and each lapping is even and uniform.</p> <p> </p> <p><strong>Reason of using Litz Wires in high frequency applications.</strong></p> <p>The DC (0 Hz) resistance of a conductor depends on its cross sectional area. A conductor with a larger area has a lower resistance. The resistance also depends on frequency because the effective cross section area changes with frequency. As frequency increases, conduction begins to move from an equal distribution through the conductor cross section toward existance almost exclusively near the surface. Depending on the conductor bulk resistivity at sufficiently high frequency all the RF current is flowing within a very small thickness at the surface. Furthermore the current concentrates nearest to the surface that abuts the highest relative dielectric contant. So round conductors such as wire or cables donot conduct much current near their axis, So the central material is not used effectively.</p> <p> </p> <p>One technique to improve the effeciency is to reduce amount of material that does not carry current by making the conductor of hollow tubing. The large surface area of the tube zonducts the current with much less resistance than a solid wire with the same cross sectional area would. The tank coils of high power radio transmitters are often made of copper tubing, silver plated on the ouside to reduce resistance.</p> <p> </p> <p>Litz wire is another method which employs a standard wire with individually insulated conductors (forming a bundle). Each thin conductor is less than a skin depth so an individual strand does not suffer a skin effect loss. The strands must be insulated from each other - otherwise all the wires in the bundle would short together, behaves like a single large wire, and still have skin effect problem. Furthermore the strands cannot occupy the same radial position in the bundle over long distances. The electromagnetic effect that cause the skin effect would still disrupt conduction. The weaving or twisting pattern of the wire in the bundle is designed so that the individual strands are on the ouside of the bundle for a distance and are inside for a distance. If each strand has a equally among every strand within the cable.</p> <p> </p> <p>In case of multiple wires or multiple turns, such as windings in transformers and inductors, the proximity effect causes losses to increase at high frequency even sooner and more rapidly than does skin effect. Proximity effect is the tendency for curent to flow in loops or concentrated distributions due to presence of magnetic fields generated by nearby conductors. In transformers and inductors, proximity effect losses are generally more significant than skin effect losses. In Litz Wire winding proximity effect may be subdivided in to internal proximity effect (the effect of other currents within the bundle) and outer proximity effect (the effect of the current in other bundles). The Litz wires are twisted or weaved just to ensure that the strand currents are equal. Where a simple bunched conductor wire can accomplish this adequately. Where skin effect would be a problem more complex Litz wire constructions can be used to ensure equal strand current.</p> <p> </p> <p>Litz wire is very effective below 500 KHz. It is rarely used above 2 MHz because at frequencies above 1 MHz the benefit becomes gradually offset by the capacitive build up between the strands. Litz wire has a higher impedance per unit cross sectional area but Litz Wire can be used at thicker cable sizes hence reducing or maintaiing cable impedance at higher frequeny.</p> <p> </p> <p><strong>Benefits of Litz Wire</strong></p> <ul> <li>Reduce A.C. Losses in high frequency winding.</li> <li>Increased Effeciency.</li> <li>Mitigation of Skin effect.</li> <li>Mitigation of Proximity Effect.</li> <li>Minimum Eddy Current losses.</li> <li>Lowered operating temperatures.</li> <li>Reduced footprint of final product.</li> <li>Substancial weight reduction.</li> <li>Avoidance of "Hot Spots".</li> </ul> <p> </p> <p><strong>Application of Litz Wire</strong></p> <ul> <li>High Frequency Transformers</li> <li>Toroidal Coils</li> <li>Stator Winding</li> <li>High Frequency Inductors</li> <li>Power Transformers</li> <li>Inverters</li> <li>Motor Generators</li> <li>Hybrid Transportation</li> <li>Wind Turbine Generators</li> <li>Communication Equipments</li> <li>Marine Acoustic Control Systems</li> <li>Induction Heating Equipments</li> <li>Sonar Equipments</li> <li>Radio Transmitter Equipments</li> <li>Switch Mode Power Supply</li> <li>Ultrasonic Equipments</li> <li>Linear Motors</li> <li>Sensors</li> <li>Antenas</li> <li>Grounding Applications</li> <li>Wireless Power Systems</li> <li>Electric Vehicle Chargers</li> <li>High Frequency Chokes</li> <li>High Frequency Motors</li> <li>Medical Sterlization Equipments</li> <li>Medical Device Chargers</li> <li>High Q Circuitry</li> <li>Tuning Circuitry in High Power Radio</li> <li>Flywheel Energy Storage</li> <li>Plasma Containment Coils</li> <li>Hearing Aids</li> <li>Relays</li> <li>Eximer Laser</li> <li>Welding Machine</li> </ul>

| Film Insulations | ||||

|---|---|---|---|---|

| Film Insulation Material | Thermal Rating | Range of wire (φ) | Advantages | Considerations |

| Polyurethane | Class 155°C MW 79-C Class 180°C MW 82-C | 0.04 to 1.10 mm | * Excellent electrical properties with high Q coils. * Easily solderable 390°C / 360°C * Excellent film adhesion and flexibility. * Good moisture and chemical Resistance | * Not recommended for applications with the possibility of severe thermal overload. |

| Polyurethane- Nylon | Class 155°C MW 80-C Class 180°C MW 83-C | 0.04 to 1.10 mm | * Good electrical properties * Easily solderable 430°C / 390°C * Excellent film adhesion and flexibility. * Improved chemical and mechanical resistance from Nylon topcoat. * Nylon overcoat provides low coefficient of friction. | * Not recommended for applications with the possibility of severe thermal overload. * Nylon topcoat is hygroscopic. |

| Polyvinyl Formal | Class 155°C MW 15-C | 0.04 to 1.10 mm | * Excellent abrasion resistance. * Excellent compatibility with transformer oils. * Good electrical properties. * Used in cryogenic applications. | * Must be stripped before soldering * Should be annealed before application varnish. |

| Solderable Polyester | Class 180°C MW 77-C | 0.04 to 1.10 mm | * Solderable 470°C * Excellent thermal properties. * Good electrical properties. * Good compatibility with varnishes and solvants. * Improved thermal overload. * Good moisture resistance. | * Low abrasion resistance compared to Nylon and amide imide topcoat materials. * Preheat before varnishing is Recommended. |

| Solderable polyester- Nylon | Class 180°C MW 78-C | 0.04 to 1.10 mm | * Solderable 470°C * Excellent thermal properties. * Good electrical properties. * Good compatibility with varnishes and solvants. * Improved thermal overload. * Good moisture resistance. * Nylon topcoat provides low coefficient of friction. | * Nylon topcoat is hygroscopic. * Preheat before varnishing is Recommended. |

| Polyester (Amide) (Imide) | Class 200°C MW 74-C | 0.04 to 1.10 mm | * Excellent flexibility and abrasion resistance . * Excellent Thermal Overload. * Excellent dielectric strength. * Excellent moisture resistance. * Good chemical resistance | * Must be stripped before soldering * Not recommended for use in oil-filled transformers. * Preheat before varnishing. |

| Polyester / Polyamideimid e overcoat | Class 200°C MW 35-C | 0.04 to 1.10 mm | * Excellent flexibility and abrasion resistance . * Excellent Thermal Overload. * Excellent dielectric strength. * Excellent moisture resistance. * Good chemical resistance | * Must be stripped before soldering * Preheat before varnishing. |

| Polyimide | Class 240°C MW 16-C | 0.04 to 1.10 mm | * Excellent flexibility. * Excellent Thermal Overload. * Excellent radiation resistance. * Excellent chemical compatibility. * High dielectric strength. * Adequate abrasion rsistance. * Low outgas | * Must be stripped before soldering. * Must be annealed before varnishing. * Will solvent craze. |

| Litz Wire Outer Insulation (Fibre) | |||

|---|---|---|---|

| Insulation (Fibre) | Recommended Max. Operating Temperature | Advantages | Disadvantages |

| Nylon | 155°C | * Good space factor * Excellent abrasion resistance * Solderable | * Hygroscopic |

| Natural Silk | 80°C | * Good space factor * Excellent abrasion resistance * Solderable | * Poor elasticity. * Can be weakened if exposed In heat for a long time. |

| Polyester | 155°C | * Solderable * Good abrasion resistance * Slightly higher maximum operating temperature than Nylon. | * Better space factor than Cotton or Glass but poorer space factor than Nylon. |

| Nomex (High Temp. Aramid) | 250°C | * Good space factor. * Good electrical properties at high Temperatures. | * Non-solderable. * Higher cost than other fibers. |

| Cotton | 105°C | * Low cost serving. * Good resistance to abrasion. | * Poor space factor compared to Nylon or Celanese. * Non-solderable. |

| Litz Wire Outer Insulation (Tape) | ||

|---|---|---|

| Insulation (Tape) | Recommended Max. Operating Temperature | Characteristics |

| Polyester (PET) | 135°C | * High dielectric strength |

| Natural Silkv | 155°C | * Good abrasion often used as binder or moisture barrier under extruded jackets and textile serves or braids. |

| Nomex (Aromatic Polyamide) | 200°C (Up to 220°C under certain conditions | * Excellent thermal properties. * Excellent electrical properties. * Excellent compatibility with varnishes, adhesives and transformer fluids. * Thinner grades are flexible. * Good resistance to tearing and abrasion. |

| Polyimide Kapton (Heat sealable & adhesive grades available) | 240°C (Up to 400°C under certain conditions.) | * Very high dielectric strength. * Very good chemial resistance. * UL 94 V-0 flame rating. * Excellent mechnical properties. |

| Glass Mica Cable Tape (GMCAB Tape) | 180°C | * Fire resistance property. * Can withstand very high environmental temperature up to 950°C in certain condition. |

| Extruded Insulations for Litz Conductor | |||

|---|---|---|---|

| Insulation (Fibre) | Recommended Max. Operating Temperature | Advantages | Disadvantages |

| PE / PP | 250°C | * Litz Coax / Triax. | * Very good dielectric properties. * Outstanding water Resistance. |

| PVC | 105°C | * Winding Wire * High frequency interconnect. * Primary in multiconductor | * Least expensive. * Excellent flame resistance. * Excellent flexibility. * Medical grades |

| Polyurethane | 90 to 105°C | * High frequency interconnect. | * Excellent abrasion resistance. * Very good flexibility. * Can be coiled. * Halogen free |