Company Information

Ask for more detail from the seller

Contact SupplierEnhance the Overall Performance and Efficiency of Your Milling Processes with Our Best Quality Rubber Shell Plates

As a prominent manufacturer and supplier of high-quality rubber products in India, we offer the best quality Rubber Shell Plates for ball mills to improve the overall efficiency and performance of milling processes. Our shell rubber liners are made from high-grade rubber materials. They are specifically designed to protect the shells of ball mills from the corrosive and abrasive effects of the grinding media and processed materials.

We offer ball mill shell plate liners based on the customer’s specifications in which design and thickness are vital factors that affect the durability, performance, and operational efficiency of ball mills. We supply flat and radial shell plates with rib, step, or wave designs.

Importance of Design and Thickness of Rubber Shell Plates

The designs impact the grinding media movement and efficiency of the grinding process. The thickness of the shell plate influences factors like wear resistance and cost. Thick shell plates are highly durable and impact absorption. With reducing thickness, the factors affected are reduction in cost and wear protection.

With easy to install, changed, or replacement facilities, we also supply Rubber Shell Plates for ball mills in modular sections helpful for you in drastically reducing downtime and maintenance costs of your processing unit. We offer custom shell plate designs based on soft and hard rock grinding materials needed for your specific application.

Flat or Radial Rubber Shell Plates

Flat shell plates are useful when requiring uniform wear distribution for less aggressive grinding conditions. Radial shell plates are expensive, but highly durable and offer exceptional performance and grinding efficiency. Based on precise grinding application, cost and performance characteristics are some important factors for choosing the design of ball mill shell liners.

For more information or your custom inquiry about Rubber Shell Plates, write to us at kedarrubber@gmail.com or Call Now - 9824444733.

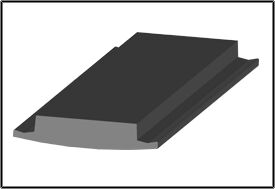

Flat Rubber Shell Plate with Taper

With increasing thickness of the flat rubber shell plates, they act as a protective barrier that prevents the mill shell from the direct impact of the wear caused by the grinding media and material. This shielding is essential for enhancing the lifespan of the ball mill and preventing structural damage. The taper helps in improving the flow of material and lowering the risk of direct contact between the mill shell and the grinding media ensuring that the rubber shell liner can impact the wear. Due to the improved impact absorption, they lower the waste of energy on mechanical stress and vibrations allowing more energy to be used for the material-breaking process and thus, enhance energy efficiency.

The taper controls the grinding media movement inside the mill. The design controls the grinding balls' trajectory ensuring that they tumble well for optimal grinding. This control ensures efficient grinding, reducing consistent particle size and enhancing milling performance.

Rubber shell plates are light in weight which makes it easy and efficient to install and remove them. They can fit easily into the mill; thus, they reduce the time to install or replace shell liners. We offer customized solutions to meet the bespoke needs of customers' specifications as per their milling process like the nature and size of grinding material or media required to process.

Customizing the rubber shell plates based on the ball mill’s needs boosts performance in different applications. For example, shallower tapers are preferable for smooth material flow and efficient grinding while steeper tapers are useful where higher impact resistance is essential.

Rubber Radial Shell Plate with Rib

Kedar Rubber offers Rubber Radial Shell Plates with ribs that give extra structural strength to the shell plate. This helps to distribute pressure across the liner evenly. Thus, protect the mill’s shell from damage by preventing excessive wear and downtime. The rib adds reinforcement to the rubber liner, makes it capable of bearing the dynamic forces of processing material and grinding media, and enables it to manage the overall integrity of the mill.

The thickness and flexibility are vital factors of rubber shell plates to enhance the absorption and reduce the risk of cracking and deformation of the shell. Thus, the rubber material with a ribbed design works as a shock absorber, shielding the grinding media impact and lowering the direct force effect on the mill shell.

The Radial shell plates with rib prolong the lifespan of the liners which in turn reduces maintenance and operational costs and also lower downtime for replacement of liners.

They also absorb more vibration caused by grinding media tumbling and thus, reduce overall noise levels in milling operations. Radial ribbed rubber shell plates also efficiently lower the inefficient grinding actions and unwanted noise that make energy-efficient processes cause energy cost reduction.

We provide customized solutions for the radial ribbed shell plate based on the specific requirements of our customers. By considering the grinding material type, mill size, and the operating environment, it is necessary to adjust the rib size, angle, and spacing to accomplish the precise grinding requirements and achieve optimal performance.