Company Information

Ask for more detail from the seller

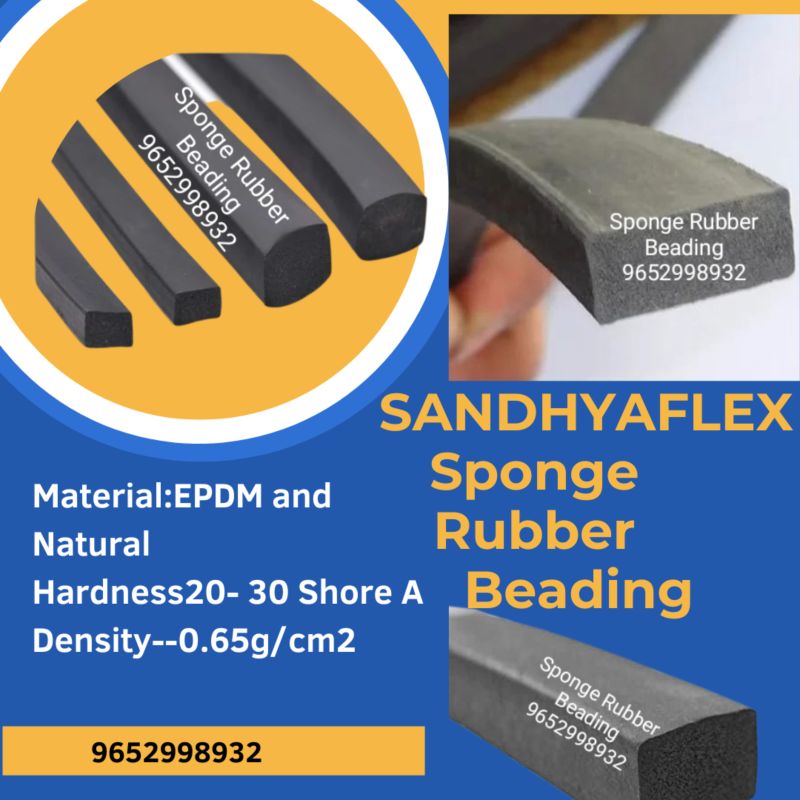

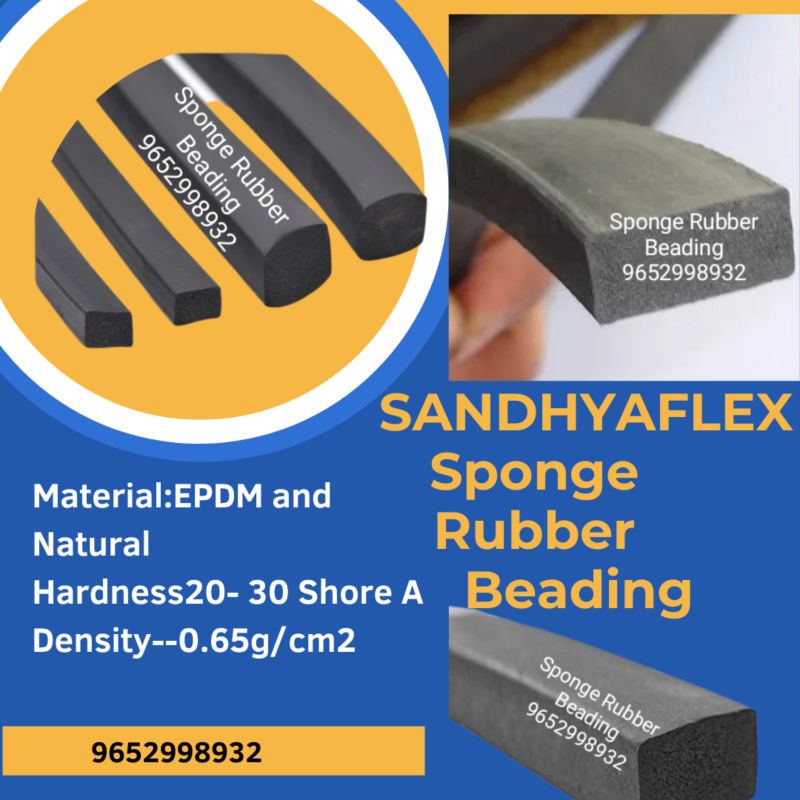

Contact SupplierSponge rubber beading refers to a type of rubber material that is typically in the form of a strip or bead with a soft, sponge-like texture. This material is often used in various applications due to its unique properties, which include flexibility, resilience, and the ability to seal or cushion gaps and joints. Here are some common uses for sponge rubber beading:

1. **Sealing and Gasketing**: Sponge rubber beading is commonly used to create seals and gaskets in various industries. It can be compressed between two surfaces to prevent the passage of liquids, gases, or dust. This is especially useful in automotive, industrial, and HVAC (heating, ventilation, and air conditioning) applications.

2. **Weather Stripping**: It is often used as weather stripping around doors and windows to provide insulation and prevent drafts, helping to maintain temperature control inside buildings and vehicles.

3. **Cushioning and Padding**: The sponge-like texture of rubber beading makes it ideal for cushioning and padding purposes. It can be used in furniture, packaging, and as padding in sports equipment to absorb shock and protect surfaces.

4. **Vibration Dampening**: Sponge rubber beading is used to dampen vibrations and reduce noise in machinery and equipment. It can be placed between moving parts or components to absorb and dissipate vibrations.

5. **Electrical Enclosure Seals**: In electrical and electronic applications, sponge rubber beading can be used to create seals and gaskets in enclosures to protect sensitive components from moisture, dust, and other environmental factors.

6. **Automotive Applications**: Sponge rubber beading is used in vehicles for various purposes, such as sealing doors, hoods, and trunks, as well as for providing cushioning in automotive interiors.

7. **Medical and Healthcare**: It is used in medical equipment and devices for sealing and cushioning purposes, particularly in applications where a soft, hypoallergenic material is needed.

8. **Marine and Boating**: Sponge rubber beading is employed in marine and boating applications to seal hatches, windows, and compartments, as well as for cushioning and shock absorption on boats and docks.

9. **Construction**: In the construction industry, sponge rubber beading can be used to seal joints and gaps in buildings to prevent water infiltration and provide thermal insulation.

Sponge rubber beading comes in various shapes, sizes, and materials to suit different applications. It is typically made from synthetic rubber compounds, such as neoprene or EPDM (ethylene propylene diene monomer), which offer good resistance to environmental factors like moisture, UV radiation, and temperature extremes. The choice of sponge rubber beading depends on the specific requirements of the application and the environmental conditions it will face.