Company Information

Ask for more detail from the seller

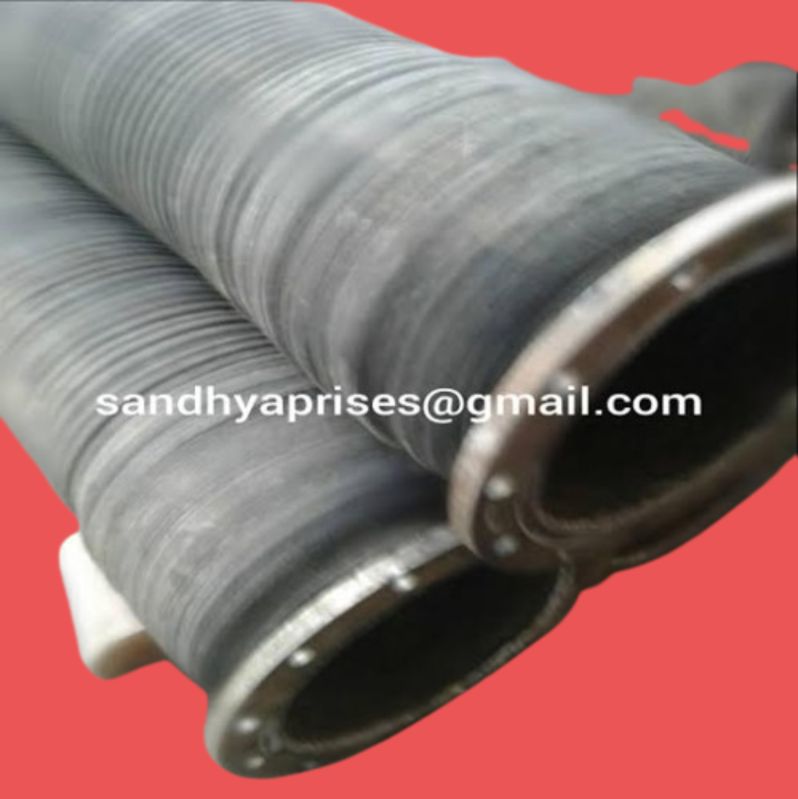

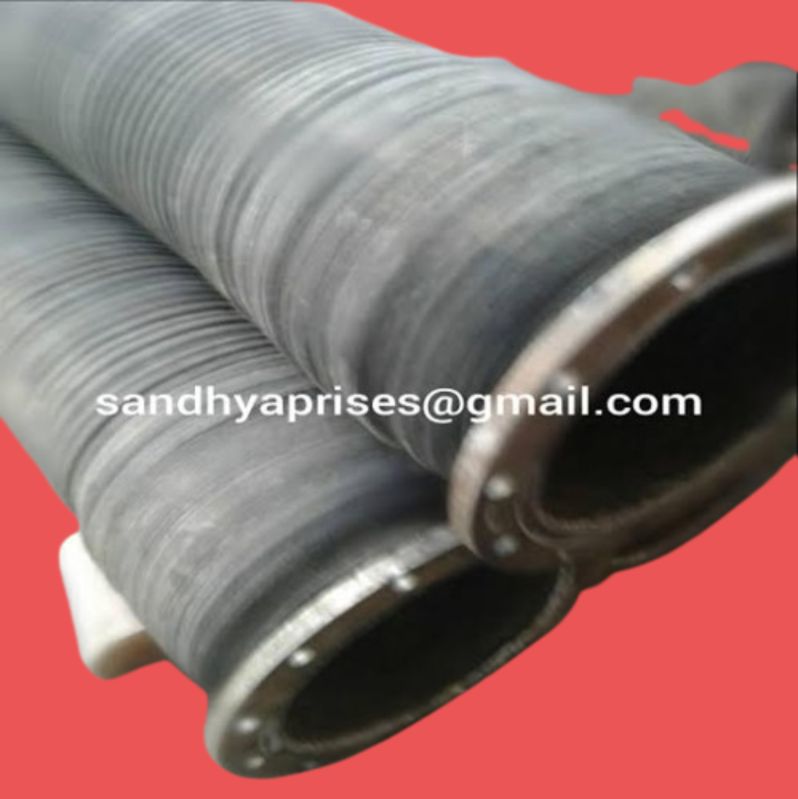

Contact Suppliersandhya enterprises manufacturer of fly ash rubber hose. sandhya enterprises manufacturer and supplier of slurry and mud rubber hose. Rubber hose for cement grouting meets is : 5137 w.p. 10kgf/cm2 min. B.p. 40 kgf/cm2 25.0 31.0 38.0 50.0 63.0 75.0 tube : highly abrasion resistant soft natural rubber compound. Reinforcement : woven/braided or spirally wound textile of high strength synthetic fibres. Electrical bonding : low resistant electrical bonding wire in-corporated between the reinforcement plies to pro vide electrical continuity along the whole length of the hose. Cover : cloth marked finish cover, resistant to weather and abrasion. Used for cement grouting at irrigations projects, buildings sites, bridges etc. Service temp. Range : -400 f to + 1580 f. Size: 3\" id to 12\" id 3\" id x 5mtr (lg) with soft end 3\" id x 5mtr (lg) with both side ms flange as per asa 150# 4\" id x 5mtr (lg) with soft end 4\" id x 5mtr (lg) with both side ms flange as per asa 150# 5\" id x 5mtr (lg) with soft end 5\" id x 5mtr (lg) with both side ms flange as per asa 150# 6\" id x 5mtr (lg) with soft end 6\" id x 5mtr (lg) with both side ms flange as per asa 150# 8\" id x 5mtr (lg) with soft end 8\" id x 5mtr (lg) with both side ms flange as per asa 150# 10\" id x 5mtr (lg) with soft end 10\" id x 5mtr (lg) with both side ms flange as per asa 150# 12\" id x 5mtr (lg) with soft end 12\" id x 5mtr (lg) with both side ms flange as per asa 150# 14\" id x 4mtr (lg) with soft end 14\" id x 4mtr (lg) with both side ms flange as per asa 150# 16\" id x 4mtr (lg) with soft end 16\" id x 4mtr (lg) with both side ms flange as per asa 150# A bulker unloading rubber hose, also known as a bulk material handling hose or bulk discharge hose, is a specialized hose designed for the unloading or transfer of bulk materials such as powders, grains, pellets, or granules from a bulk carrier or silo to a storage facility or processing equipment. It is commonly used in industries such as agriculture, mining, chemical processing, and construction. The key features and characteristics of a bulker unloading rubber hose include: 1. Material compatibility: Bulker unloading rubber hoses are constructed with a lining made of abrasion-resistant rubber or synthetic materials. This lining is specifically designed to withstand the abrasive nature of bulk materials and prevent wear and damage to the hose during unloading or transfer. 2. Reinforcement: The inner lining is reinforced with high-strength textile or steel wire braids or spirals to provide structural integrity and prevent the hose from bursting under pressure. The reinforcement enhances the hose's ability to handle the demanding conditions of bulk material transportation. 3. Flexibility: Bulker unloading rubber hoses are designed to be flexible, allowing for easy handling and installation. This flexibility enables the hose to accommodate movement during the unloading process and reach different points in the material handling system. 4. Pressure resistance: The hose is engineered to withstand the specific working pressures involved in bulk material transfer. It is designed to maintain its integrity and prevent leaks or bursts during operation. 5. Size and fittings: Bulker unloading rubber hoses are available in various diameters and lengths to suit different application requirements. They can be fitted with standard couplings or connections for easy attachment to bulk carriers, silos, or other material handling equipment. 6. Chemical resistance: Depending on the specific application, bulker unloading rubber hoses may be designed to have chemical resistance properties to withstand the corrosive nature of certain materials or the presence of chemicals used in the process. Regular inspection and maintenance of the bulker unloading rubber hose are necessary to identify signs of wear, damage, or deterioration. Any worn or damaged hoses should be replaced promptly to prevent leaks or disruptions in the bulk ma