Company Information

Ask for more detail from the seller

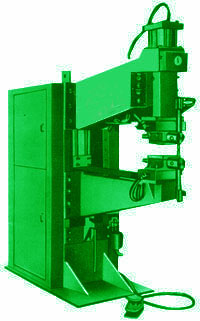

Contact SupplierSTANDARD FEATURES - ALL MACHINES :

MAIN SUPPLY-415 Volts. Single Phase (2lines of 3 phase supply) 50 Hz.

AIR OPERATION :

Spring follow-double acting cylinder; Air line filter, lubricator, regular pressure gauge; Electric Solenoid Valve; Machine machanically capable of 125 operations/minute. ELECTRICAL - Foot Switch/Palm Button; Weld/No Weld Switch;Pressure Switch; Transformer in Class 'F' Insulation. provide with 8 current regulating taps between 55% and 100% output; Contrail circuits at less than 110 Volts. COLLING - By water with separate circuits for main Transformer, Secondary conductor and Electorder. die (in case of projection Welders) Thyristors. Each circuit to terminate in sight cup provide; wheel valves each circuit. PROTECTION - Transformer, Thyristors by themosate against water failure; Luminous overload indicator on panel.

ELECTRONIC CONTROLS :

Microprocessor based solid state Electronic Control with Thyristor Contact or unit.

SPECIAL FEATURES AVAILABLE ON REQUEST :

| SPECIFICATIONS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||