Company Information

Ask for more detail from the seller

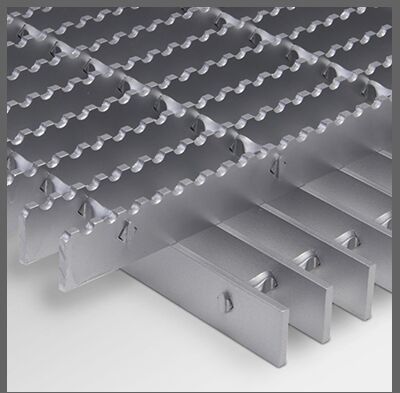

Contact SupplierA serrated flat bar is a type of metal bar that features a serrated or jagged surface pattern. It is commonly used in various industries, such as construction, manufacturing, and infrastructure, for applications that require enhanced grip or anti-slip properties.The serrated surface of the flat bar provides increased traction, making it particularly useful in environments where slip resistance is important, such as walkways, stair treads, ramps, and platforms. The serrations create multiple contact points between the bar and the user’s footwear, reducing the risk of slips, trips, and falls.Serrated flat bars are available in different materials, such as carbon steel, stainless steel, and aluminum. The choice of material depends on factors such as strength requirements, corrosion resistance, and cost considerations. Carbon steel serrated flat bars are widely used due to their strength and affordability.

Features:

Serrated flat bars

Serrated flat bars are characterized by their serrated or notched surface, which provides excellent grip and slip resistance. The serrations create raised ridges or teeth, enhancing traction and minimizing the risk of slips and falls, even in wet or oily conditions. This makes serrated flat bars an ideal choice for flooring, stair treads, ramps, walkways, and other areas where slip resistance is crucial.

Flat Profile

Serrated flat bars have a flat, rectangular profile, making them easy to handle, transport, and install. Their uniform thickness and consistent dimensions allow for seamless integration into various structural elements, such as platforms, gratings, and catwalks.

Durable Materials

Our serrated flat bars are constructed from high-quality structural steel or other durable materials, ensuring exceptional strength, longevity, and resistance to corrosion, impact, and environmental factors. This durability makes them suitable for both indoor and outdoor applications.

| Sizes in mm | Average KG/MTR | Weight KG/FT |

|---|---|---|

| 25 x 4.8 | 0.89 | 0.27 |

| 25 x 5 | 0.93 | 0.28 |

| 25 x 6 | 1.12 | 0.34 |

| 30 x 4.7 | 1.06 | 0.32 |

| 30 x 5 | 1.13 | 0.34 |

| 30 x 6 | 1.35 | 0.41 |

| 30 x 7 | 1.58 | 0.48 |

| 30 x 8 | 1.81 | 0.55 |

| 32 x 4.7 | 1.13 | 0.35 |

| 32 x 5 | 1.21 | 0.37 |

| Sizes in mm | Average KG/MTR | Weight KG/FT |

|---|---|---|

| 32 x 6 | 1.45 | 0.44 |

| 35 x 5 | 1.32 | 0.40 |

| 38 x 4.7 | 1.36 | 0.41 |

| 38 x 5 | 1.44 | 0.44 |

| 40 x 5 | 1.52 | 0.46 |

| 40 x 6 | 1.83 | 0.56 |

| 40 x 8 | 2.43 | 0.74 |

| 45 x 5 | 1.72 | 0.52 |

| 50 x 5 | 1.91 | 0.58 |

| 50 x 6 | 2.30 | 0.70 |