Listing ID #4650453

Company Information

Ask for more detail from the seller

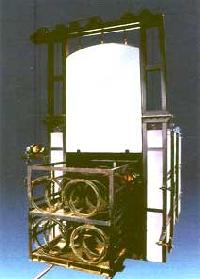

Contact SupplierShaker Hearth Heat Treatment Furnace in fact called Reciprocating and Rotary Agitation write Furnaces while responding shaker movement bestows idleness to the work plate display in the hearth of the heater with uniform warming to the principle workload general case profundity warm is accomplished.

The Furnace are by and large utilized for the light weight parts that are to be carburized to case profundity of 0.3 mm. Shaker hearth heaters utilize a plate for the vehicle of Work pieces from a bay zone to a release zone, and such plate are ordinarily upheld inside the heater upon metal or headstrong slides or upon rollers or notwithstanding holding tight arms. Such kinds of backings are liable to very fast Wear and their restoration requires expulsion from the Furnace.

Primary Process of the Furnace:

Austempering : increment quality, sturdiness, and diminish mutilation.

Solidifying: increment the hardness of a metal for better protection.

Remarkable Features:

Extra Information: