Company Information

Ask for more detail from the seller

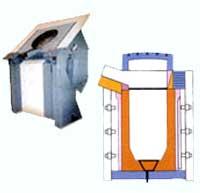

Contact SupplierOur Silica Ramming Mass are high on purity. These are resistant to abrasion and spalling. They find their vast usage in various industries. We bring superior quality silica ramming mass which is acidic in nature having the melting point 3274 F. Our acidic ramming mass is widely used in the lining of induction furnaces.

Let̢۪s discuss some more points regarding the physical as well as chemical properties like:

Nature : Acidic

Melting : 3274oF (1700oC)

Acidic ramming mass is used in the lining of induction furnaces. Quality of acidic ramming mass is directly related to the heating performance of the furnaces. Better quality of lining results in the smooth working of furnaces, optimum output and better metallurgical control.

Granulometric composition of commercial silica ramming mass size percentage: