Listing ID #1490990

Company Information

Ask for more detail from the seller

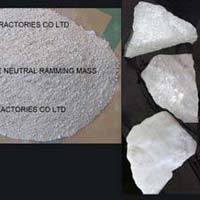

Contact SupplierKirti Mineral Works has the necessary technical expertise as well as a large production facility in Raigarh, Chhattisgarh. Experienced personnel with a thorough understanding of refractory materials combine different grain sizes of silica in precisely the proper quantities to create silica ramming mass for ladle lining suited for a variety of induction furnaces.

The ability to endure readily absorbing thermal shocks is a crucial feature of ramming mass. It also does not fracture as a result of numerous power outages during induction furnace operation. We produce high-quality silica ramming mass with a high density of silica quartz. This is why it is a well-known brand among silica ramming mass goods made in India.

Our Ladle Ramming Mass can withstand extremely high temperatures. It can function at full capacity. It offers great lining performance as well as good heat conductivity. It is capable of withstanding the strains imposed by heat cycles while in use. This is also notable for its good volume stability, little apparent porosity, and improved heat stability of the structure.

At very high temperatures, Ladle Ramming Mass is likely to be employed. It may be used to make a variety of refractory materials. When opposed to other refractories, it also has reduced heat losses. For coreless electric arc furnaces, Ladle Ramming Mass can be utilized.