Company Information

Ask for more detail from the seller

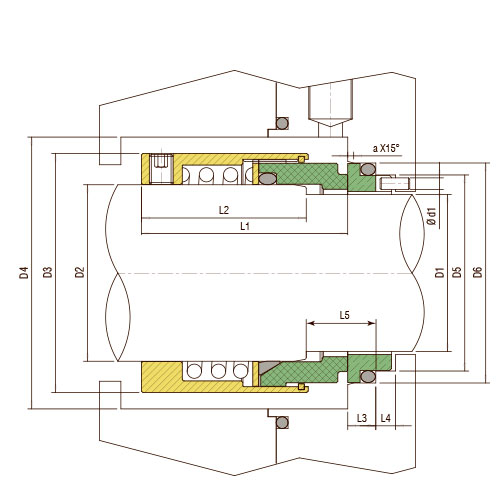

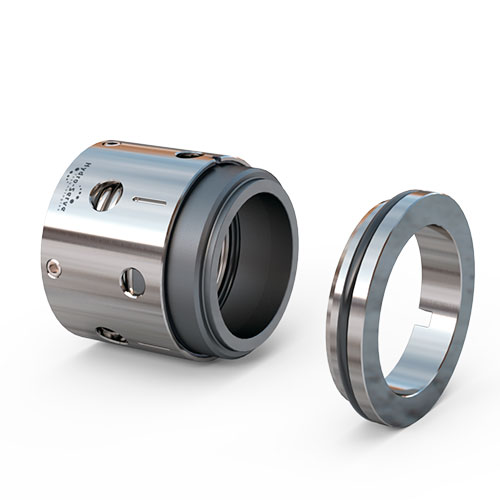

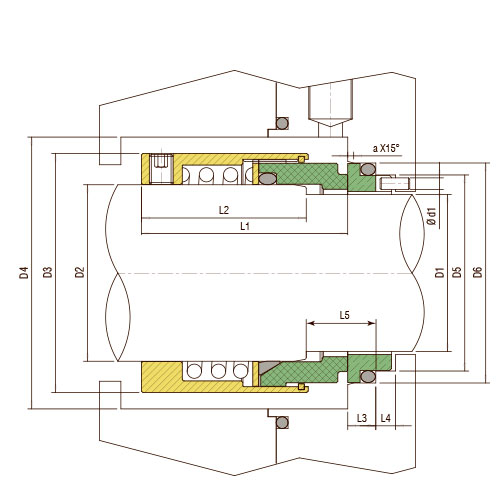

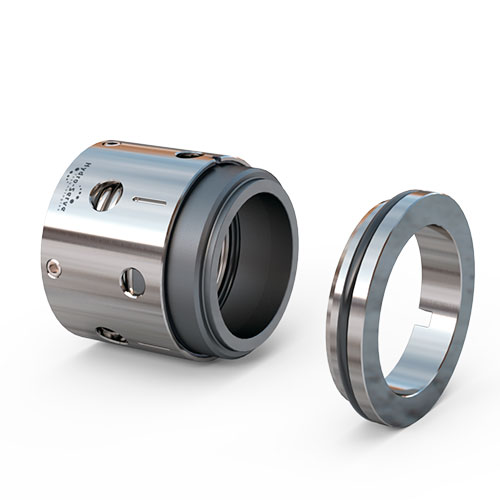

Contact Supplier The B75 and B76 single coil spring seals are innovative sealing solutions that offer both hydraulically unbalanced and balanced designs. With their compact and robust design, these seals excel at handling challenging fluids such as sludges, slurries, polymerizing fluids, and thick syrups. Their versatile nature allows for seamless adaptation to various operational requirements.

One notable advantage of these seals is their ability to switch between hydraulically unbalanced and balanced designs simply by changing the seal ring insert. In the hydraulically unbalanced configuration, the seal generates a higher sealing force, making it suitable for viscous fluids and those containing solid particles. This design ensures effective sealing performance even in demanding conditions.

On the other hand, by replacing the seal ring insert, the seal can be transformed into a balanced version. This design reduces friction and wear, making it ideal for cleaner fluids and lower viscosity applications. The balanced configuration helps to prolong the seal's lifespan and maintain sealing efficiency over time.

Applications:

Material:

Operating Parameters: