Company Information

Ask for more detail from the seller

Contact SupplierDescription

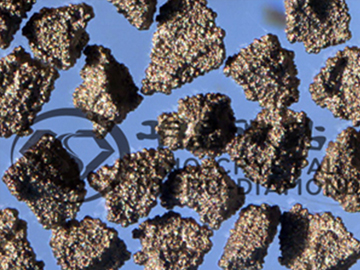

coated diamond is divided into electrolytic and chemical plating, it includes ni coating,cu coating,ti coating ,cr coating etc. Coated diamond effectively increase holding force between diamond and bonding, reduce thermal shock, protect diamond against oxidation and graphite, lengthen product lifetime.

Usage

titanium coated products can improve the retention between diamond and bond,prevent the diamond from peeling off, and extend the service life of diamond tools.

Electroplating nickel products can mainly used in resin bond products with dry and wet abrasives effectively improve the holding force, with good thermal stable ability,avoid carbonization in high speed cutting.chemical plating nickel products mainly used in resin bond products with dry and wet abrasive, no external current conditions ,and deposited metal on diamond surface by processing of self-catalytic redox reactions, form the thickness and density of nickel-plated.

Coating work can be applied on all our series diamond powders.