Company Information

Ask for more detail from the seller

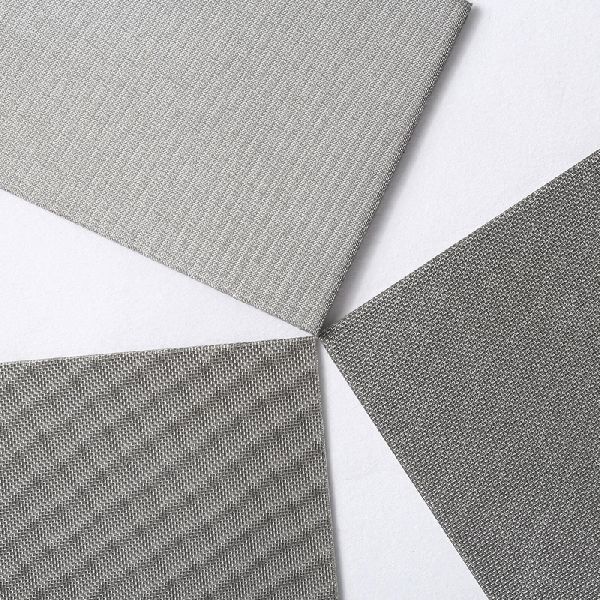

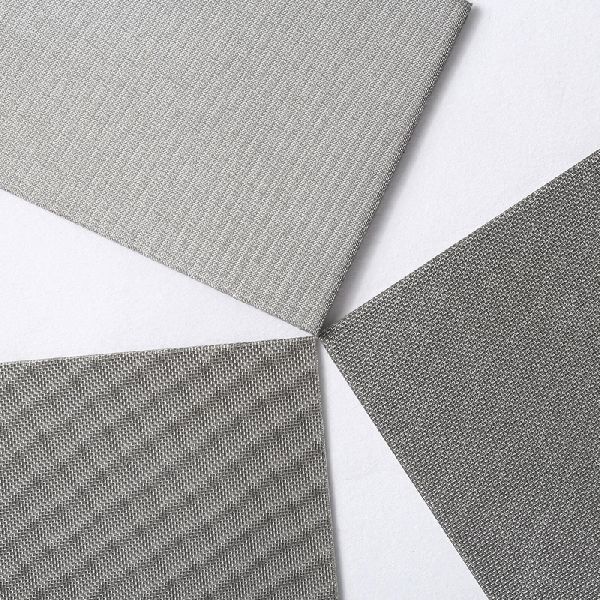

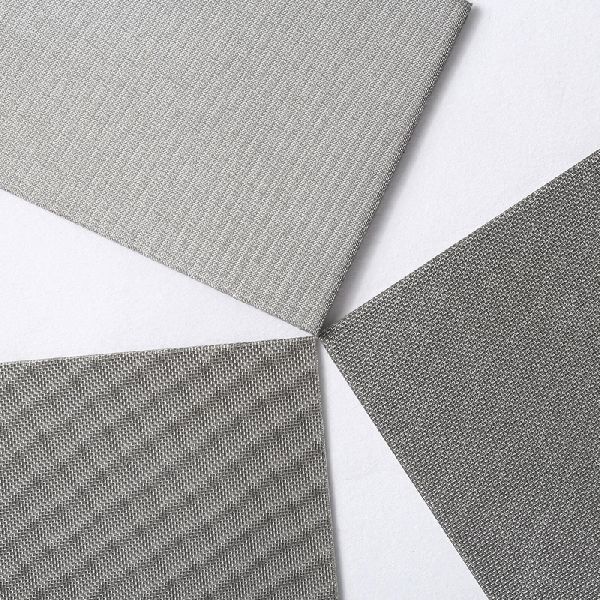

Contact SupplierSS 316L 5-layer Stainless Steel Sintered Woven Wire Mesh Filter

QL sintered wire mesh is a typical surface filtration made up of several laminated layers of woven wire mesh by sintering. Some layers are used for high precision filtration and others for protecting and reinforcing. Stainless steel types 304L and 316L are commonly applied and other metals or alloys (hastelloy, monel, etc... ) are also available on request.

Different wire diameters and weaving methods will create different wire mesh accuracy to match various demands. It is possible to design wire mesh with specific thickness, pore size, etc. QL sintered wire mesh is an enormous class of new material with comprehensive properties that are superior to sintered metal powder and porcelain.

Characteristics:

1. High mechanical strength and stability

2. High permeability

3. No delamination

4. Easy to clean(back flushing)

5. Easy to shape

6. Corrosion resistant

Applications:

1. Polymer filtration

2. Hydraulic fluid filtration

3. Water conditioning

4. Pharmaceutical processing

5. Fluidized beds

6. Air diffuser

Technical Parameters of Five-layer Plate:

Series

Filtration Rating

(μm)

Porosity

(%)

Thickness

(mm)

Weight

(kg/ m2)

Tensile Strength

(kgf/m m2)

5KW5

2

30~50

1.6~1.7

8.4~9.1

11~13

10KW5

5

15KW5

10

20KW5

20

30KW5

25

50KW5

40

High dirt holding capacityLayers: 5High temperature and corrosion resistanceType: 10kwNominal filter rating: 5μmAbsolute rating 98%: 12 to 14μmMean B.P.P: 3300 to 3700PaResistance coefficient: 12Porosity: 30 to 38%Weight: 8.4 to 9.1kg/m2Thickness: 1.6 to 1.7mmTensile strength: 11 to 13kgf/mm2Sintered by two or more layers (2 to 12 layers) of stainless steel wire mesh, which are compressed and Sintered together in vacuumMicron rating ranges from 0.5 to 300 microns